Fiber optic cable manufacturing:

The manufacturing process of optical cable is generally divided into the following processes:

1) Selection of optical fibers: select optical fibers with excellent transmission characteristics and qualified tension.

2) Optical fiber dyeing: standard full-color information differentiation

3) Secondary extrusion: Use plastic with high elastic modulus and low coefficient of linear expansion to extrude a pipe of a certain size, load it with moisture-proof and waterproof gel, and store it for several days (no day)

4) Optical cable stranding: Several extruded optical cables are twisted together with the reinforcing unit.

5) Optical cable outer sheath: add a layer of sheath to the stranded optical fiber cable.

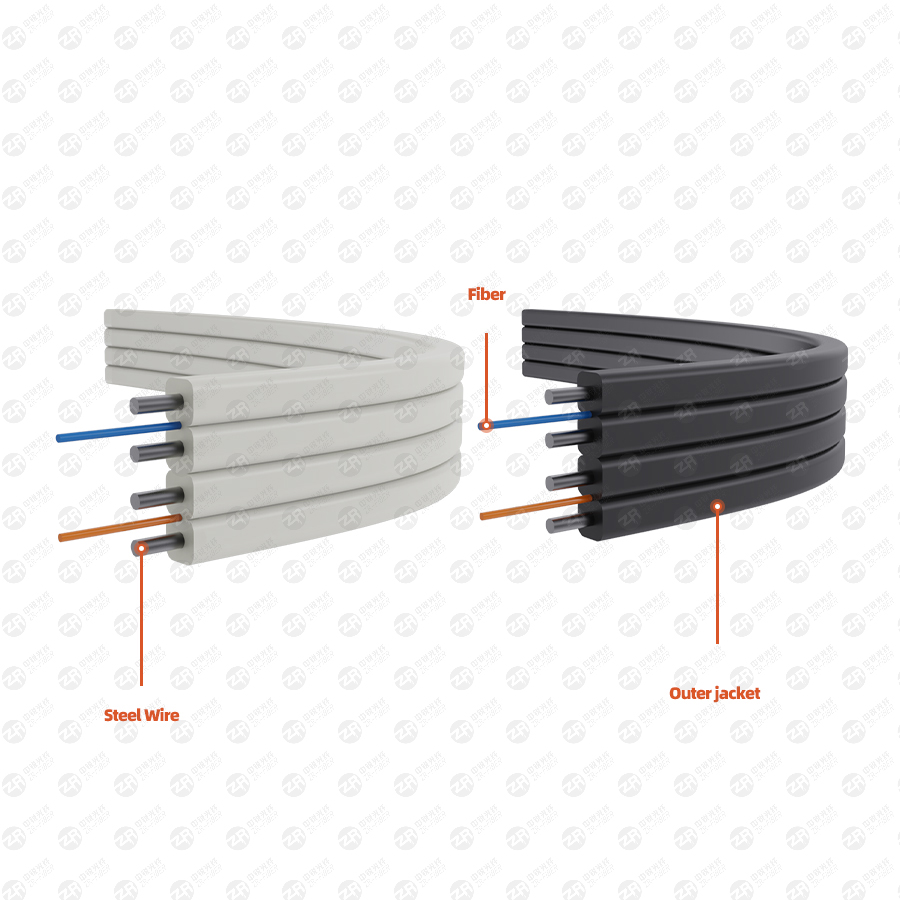

Optical cable type:

1) According to the laying method, there are self-supporting overhead optical cables, pipeline optical cables, armored buried optical cables and submarine optical cables;

2) According to the structure of fiber optic cable: tube fiber optic cable - fiber optic cable, compact fiber optic cable, ribbon fiber optic cable, non-metallic fiber optic cable and branch fiber optic cable.

3) According to the application: long-distance communication optical cable, short-distance outdoor optical cable, hybrid optical cable and building optical fiber optical cable.

Over the years, we have developed a proven set of methods and experience in fiber optic cable construction. So what should be paid attention to in outdoor construction of optical cables?

The most important thing is to choose a suitable long-distance cable laying path. There is no need here for the shortest path to be the best, but also be mindful of the right to use the land, with the greatest potential for impact or burial. During construction, care should be taken not to make optical cables through heavy or hard perforations. When the optical cable rotates, the turning radius is greater than 20 times the diameter of the optical cable gauge.

Aerial pull rope winding mode, which is an overhead fiber optic cable structure:

Overhead hanging line hanging, this method is simple and cheap, and is the most widely used in my country, but hooking, hanging, and finishing are more time-consuming. Self-supporting overhead mode has high requirements for line drying, construction is difficult, m is more stable, and maintenance workload is less. When overhead, a guide device should be added to the dry place of the optical cable conductor to avoid grounding the optical cable conductor. Take care to reduce friction when pulling the cable. Each valve stem should have a piece of fiber optic cable for expansion and contraction

Pay attention to the reliable grounding of metal objects in the optical cable. Especially in mountainous areas, high-power grid areas and many areas generally have 3 points per kilometer, and even choose non-metallic optical cables

Outdoor duct and cable construction:

Before construction, check the occupancy of the pipes, clean and place the plastic sub-pipes, and put in the traction lines. The length of a layout should not be too long (generally 2KM), and the wiring should be pulled from the middle to both sides.

Calculate the length of the fabric and make sure there is enough reserved length. Optical cable traction i E. The equipment must follow the optical cable entry and exit, do not directly mop the floor.F. Reliable grounding generally does not exceed 120 kg, the core of the traction cable should be strengthened, and the cable head should be waterproof and strengthened.

Direct buried optical cable laying:

The depth of the direct buried optical cable should be in accordance with the standard.

Optical cables laid in buildings: When laying: The trenches should be flat and firm, and if necessary, some sand, cement or supports can be pre-filled.

When the optical cable passes through the wall or floor, a plastic pipe with a mouth guard should be added and the pipe should be filled vertically. Special attention should be paid to the bearing of the optical cable. Generally, it should be fixed once every two layers.

Selection of fiber optic cable: A certain number of plastic pipes can be used in the building in advance, and then the fiber optic cable can be laid by traction or vacuum, and the fiber optic cable can be applied later.

In addition to selecting the number of fiber cores and fiber types, fiber optic cables can also choose fiber optic cable jackets according to the use of the fiber.