Compared to copper cables, fiber optic cables are very fragile and easily damaged, especially during fiber optic construction. So the question is, what are the wrong operations of optical fiber construction? Hurry up and follow ZR Cable to take a look down!

What are the wrong operations of optical cable construction: do not clean the optical fiber before fusion splicing

Cleaning bare fibers is a very important step before fiber splicing. It should be noted that the bare fiber should be cleaned first, and then the bare fiber should be cut. In fact, nothing is cleaner than a freshly cleaved fiber endface, so you should never try to clean the fiber after cleaving, as this will contaminate the fiber endface. When cleaning bare fibers, it is strongly recommended that operators use fast-evaporating, non-flammable precision cleaning fluids.

What are the wrong operations of optical cable construction?

Improper use of cutting tools

Whether the fiber end face is smooth or not has an important influence on the performance of the spliced or terminated fiber. In the past, fiber cleaving knives were commonly used to manually cleave fibers, requiring operators to be systematically trained and skilled. Now, with the development of technology, modern automatic cutting tools are very common in the market, which can improve the safety of the operator and protect the optical fiber. In general, the automatic cutting tool is an important tool to ensure the qualified fiber end face after cutting.

No calibration before fiber splicing

It is very important to calibrate the fusion splicer. In particular, the intensity or current intensity of the arc needs to be adjusted frequently to ensure that the size of the fusion joint is appropriate, so as to ensure that the mechanical strength of the fusion joint is strong enough and the optical performance is good enough. This is especially important when working with air pressure changes or at high latitudes. In fact, the calibration work is very easy to do. For most fusion splicers, as long as the fiber is simply put on, it is like doing fusion splicing. However, when calibrating, you do not need to actually fuse, but go to the maintenance menu of the fusion splicer, select the option of arc calibration or arc backtest, and the fusion splicer will tell the operator how to calibrate step by step. After the calibration is complete, the fusion splicer will also remind you that the calibration is complete or if the entire system needs to be re-tested.

Fiber microbends

Microbending of the optical fiber is generally caused by excessive pressure on the optical fiber. Microbending of the optical fiber can cause signal quality degradation, and this problem is difficult to detect with the naked eye unless an OTDR is used to check.

Fiber overbend

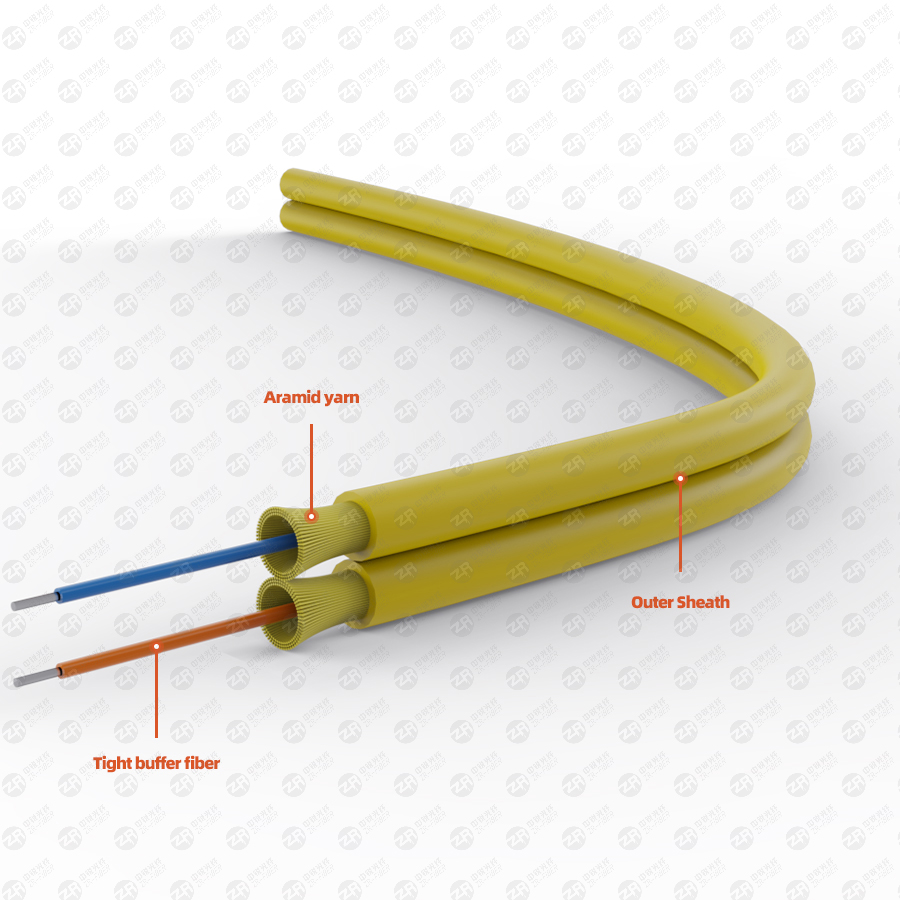

All optical cables have their own minimum bending radius. Therefore, we should pay attention not to exceed the minimum bending radius of the optical cable when constructing the optical cable, so as to avoid damage to the optical cable and the optical fibers in the sheath.

Reuse wipes/cloths

Reusing wipes/cloths is a trivial act, because when a connector is cleaned with a wipe/cloth, the wipe/cloth is dirty and gets oil from your hands And the gray layer, if it is used to wipe other connectors, it will contaminate other connectors. Of course, if you really want to save money, you can buy the smallest size wipes/cloths.

What are the wrong operations of optical cable construction: do not check and clean the connector end face before installation

The end face of the connector is also a place that is easily polluted by dust and oil. Therefore, when installing the connector, we should check and clean the end face of the fiber optic connector.

The above is all about the wrong operation of optical cable construction. The above are all long-term problems in optical fiber communication. These problems slow down the optical fiber network and often bring network failures. However, in fact, as long as the network construction personnel strictly abide by the Standard steps, along with a little caution, will do a good job of avoiding these problems.