There are two main problems in erecting outdoor ADSS fiber optic cables on high-voltage transmission line towers:

1. The distance between the towers is long. In order to ensure the safe distance between the phase line and the optical cable, the sag of the optical cable must be strictly limited. This has high requirements on the tensile modulus and strength of the optical cable. For this reason, FRP is generally used as a reinforcement in the ADSS center, and sometimes aramid is placed in the sheath as an auxiliary to control the strain of the ADSS optical cable when it is stretched. . Aramid has a higher tensile modulus and lower specific gravity than FRP, but is expensive.

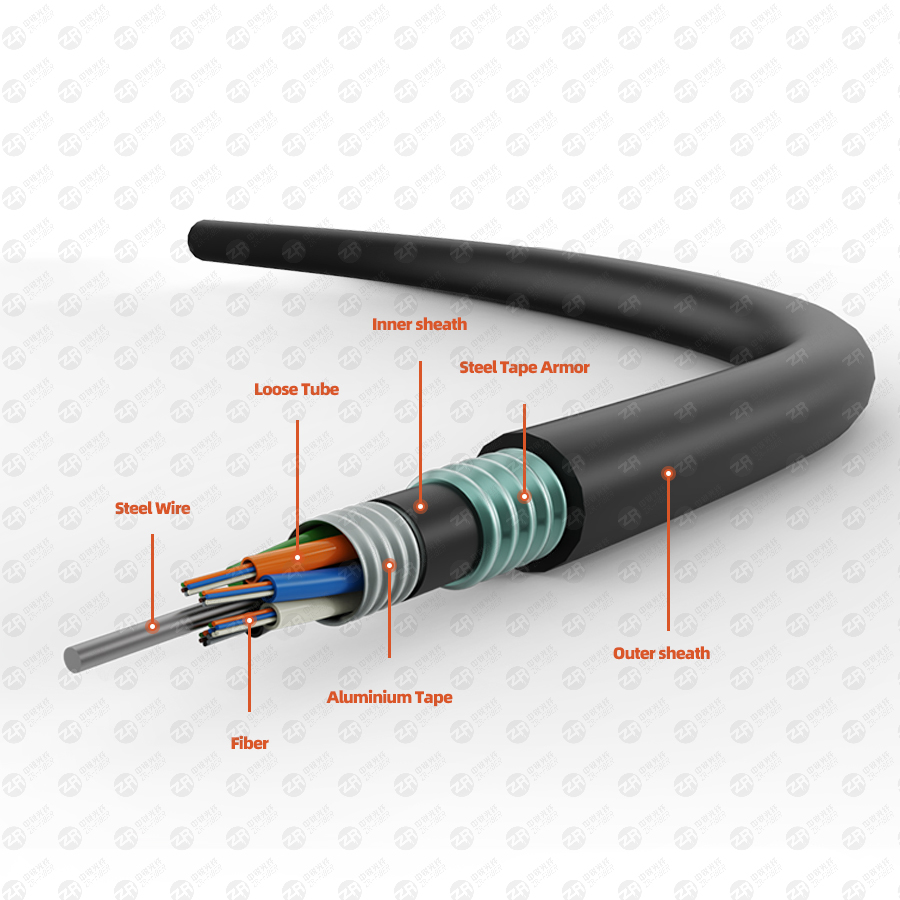

ZR ADSS cable

2. Another problem is that the ADSS optical cable is erected in the strong electric field of the high-voltage line. The distribution content between the ADSS optical cable, the high-voltage line and the ground is coupled with voltage on the surface of the optical cable, and there is current on the surface of the optical cable in wet seasons. When the cable is semi-dry and wet, arcing occurs in the dry area, and the heat of the arcing can erode the jacket. Therefore, ADSS optical cables are generally used in transmission lines below 110k.

In order to make the outdoor ADSS fiber optic cable can be used on higher transmission lines, it is solved from two aspects. A new material has been found to have a high resistance to arcing without damage; another method is to eliminate arcing fundamentally: on both sides of the tower, 50m long before and after, put a rod with appropriate conductivity Fixed on the erected ADSS fiber optic cable to control the distribution of the electric field, thereby eliminating arcing.

ZR ADSS optical cable application scenarios

Through the introduction of ZR Fiber, I believe that everyone has an understanding of how the hanging point of outdoor ADSS fiber optic cable is determined. If you want to know more about ZR fiber jumper products, welcome customers to come and consult.