Optical fiber transmission has the advantages of wide transmission frequency, large communication capacity, low loss, no electromagnetic interference, small diameter of optical cable, light weight, rich source of raw materials, etc., so it is becoming a new transmission medium. When light is transmitted in an optical fiber, a loss will occur, and this loss is mainly composed of the transmission loss of the optical fiber itself and the splice loss at the optical fiber joint.

Once the optical cable is ordered, the transmission loss of the optical fiber itself is basically determined, and the splice loss at the optical fiber joint is related to the optical fiber itself and on-site construction. Efforts to reduce the splice loss at the optical fiber joint can increase the optical fiber relay amplification transmission distance and improve the attenuation margin of the optical fiber link.

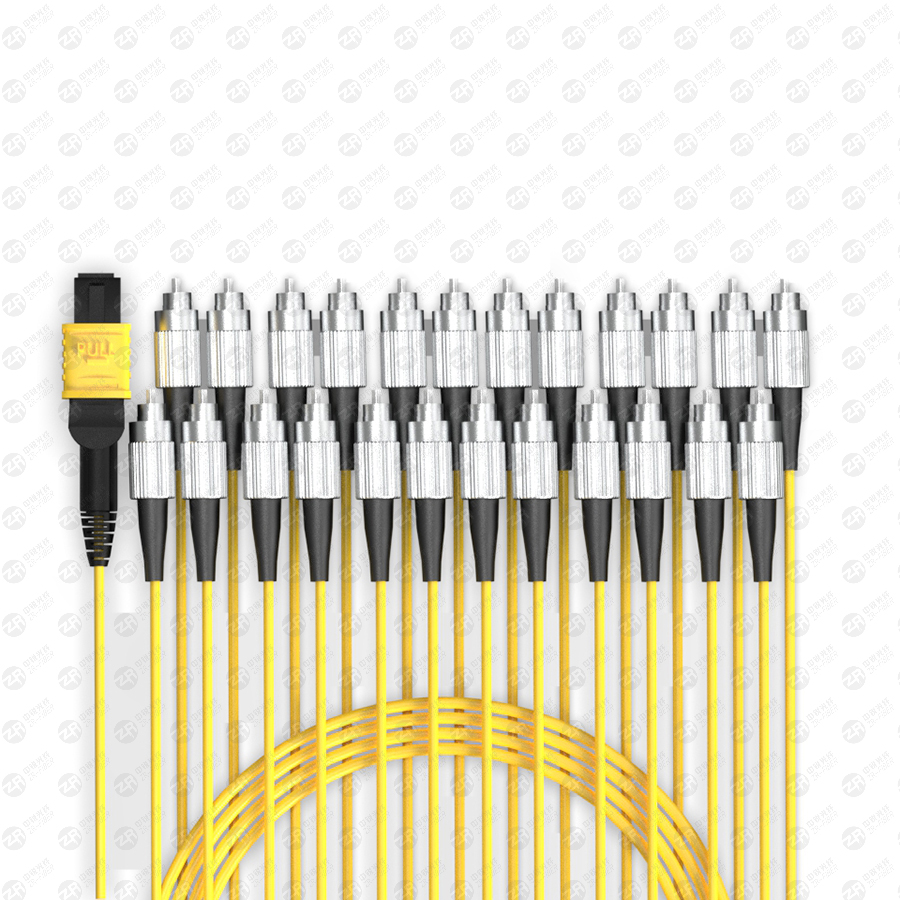

The cold splicing of optical fibers is used for optical fibers butt optical fibers or optical fibers butt pigtails. This is equivalent to making joints. This kind of cold splicing is called optical fiber cold splicing. The optical fiber cold splicer is used when the two pigtails are butted. The main component inside is a precise v-groove. After the two pigtails are pulled out, the cold splicer is used to realize the butt of the two pigtails.

It is easier and faster to operate and saves time than welding with a welding machine. There are generally two forms of cold splicing: the first field quick connector that ends up; the second type of cold splicing for optical fiber butt joints. With the rapid development of FTTH fiber-to-the-home, the demand for optical fiber cold splices has also greatly increased.

Fiber Cold Splice

Optical fiber quick connectors and optical fiber cold splices will play an irreplaceable role in FTTH access. The field termination technology of optical fiber quick connectors just solves this problem. The operation is convenient and fast without fusion splicing, and the connection cost is low, which truly realizes access anytime, anywhere. . It is used for optical fiber butt optical fiber or optical fiber docking pigtail, which is equivalent to making a joint, (fiber docking pigtail refers to the butt joint between the optical fiber and the core of the pigtail, not the pigtail head mentioned by the former), which is used for this kind of cold splicing. Something called a fiber optic cold splicer.

The optical fiber cold splicer is used when the two pigtails are butted. The main component inside is a precise v-groove. After the two pigtails are pulled out, the cold splicer is used to realize the butt of the two pigtails. It is easier and faster to operate and saves time than welding with a welding machine. Fiber optic cable splicing Fiber optic cable splicing is a meticulous work, especially in end face preparation, splicing, fiber coiling and other links, requiring the operator to observe carefully, consider carefully, and operate in a standardized way. When light is transmitted in an optical fiber, a loss will occur, and this loss is mainly composed of the transmission loss of the optical fiber itself and the splice loss at the optical fiber joint.

Once the optical cable is ordered, the transmission loss of the optical fiber itself is basically determined, and the splice loss at the optical fiber joint is related to the optical fiber itself and on-site construction. Efforts to reduce the splice loss at the optical fiber joint can increase the optical fiber relay amplification transmission distance and improve the attenuation margin of the optical fiber link. The difference between cold splicing and fusion splicing Hot splicing requires the use of a fusion splicer and a fiber cutter.

The two optical fibers are connected together, no other auxiliary materials are required. The advantage is that the quality is stable and the connection loss is small (about 0.03 to 0.05). The disadvantage is that the equipment cost is too high, the power storage capacity of the equipment is limited, and field operations are limited. Cold splicing does not require much equipment, just a fiber cutter. But each contact needs a quick connector (it can be said to be the mainstream operation in the future), which costs about 5 to 10 yuan.

The advantage is that it is easy to operate and suitable for field operations. The disadvantage is that the loss is too large, about 0.1 to 0.2dB per point. "Cold splices" At present, there are few domestic manufacturers that can directly produce them, and the cost is high. There is no room for choice in business and technical services. The second is the use of matching liquid in the cold splices. Due to less use, short time and aging Questions take the test of time.