Unlike the BNC connectors commonly used in the A/V industry, fiber optic connectors have gradually developed as fiber optic technology continues to mature. The effect of copper wire connectors on the signal loss of AV systems is generally not very large, but the optical fiber connection is different, it will play a very large role in each interface in the transmission system.

Let's take a look at some of the problems that arise in the physical connection of optical fibers. The optical transmission equipment itself can command the connection, but in some cases, most or almost all optical transmission connection selections are made by humans. The amount of signal lost in the signal transmission process of the optical fiber cable is mainly determined by the quality and type of the optical fiber cable used, and each connection end will produce a certain amount of signal loss. Depending on the type of fiber optic connector selected by the user, the total amount of signal loss at the connection end may add up to more than the signal loss generated by the fiber optic cable itself.

The optical fiber connector

maintain the normal operation of the system

In the design of the optical fiber system, the system can operate normally, and it has achieved a very good effect. In the system design, we need to consider some unexpected problems that may occur in the system, and make the system achieve the normal operation effect. In system design, we should take into account the worst possible situation of the system, and make corresponding plans to expect better operating results. Fiber optic connector designers must keep this concept in mind.

In system design, safe and stable system connection requires smooth and square fiber ends. End-to-end connections must be accurate, even down to microns, millionths of a meter. Commonly used multimode fibers have diameters ranging from 50-62.5 microns, while single-mode fibers are only 8-9 microns in diameter. Comparing this diameter to the diameter of a single hair (17-180 microns), it can be seen that any error can lead to catastrophic losses.

Fiber optic connections have very strict requirements on the precision of the equipment, so the connectors must be very clean. Fiber optic connectors and accessories are usually housed in a sleeve. A fingerprint or external dust may seriously affect the performance of the connector and even cause transmission failure. Therefore, when the connector is not connected, it should be kept in a clean protective sleeve. inside.

When connecting, we should also wedge the fiber optic connector tightly. In all the current fiber optic connector designs, it is carried out through "ferrules" to ensure that the connectors are matched accurately. The fiber optic termination is clamped inside the ferrule by gluing or crimping, making it a permanent component. After the built-in fiber is inserted, the ferrule end is ground smooth to provide a smooth interface for the connector fiber connection.

Ferrules are usually made of relatively hard materials such as ceramics, of course, they can also be made of stainless steel, plastic or tungsten carbide. is 1.25 mm. Since the functional characteristics of the ferrule can be produced according to the precision requirements, it has become the primary and important determining characteristic of the fiber optic connector. Among the many connection ferrules, the spring-loaded container connection ferrule ensures coaxial alignment between the optical fiber and the LED or laser source.

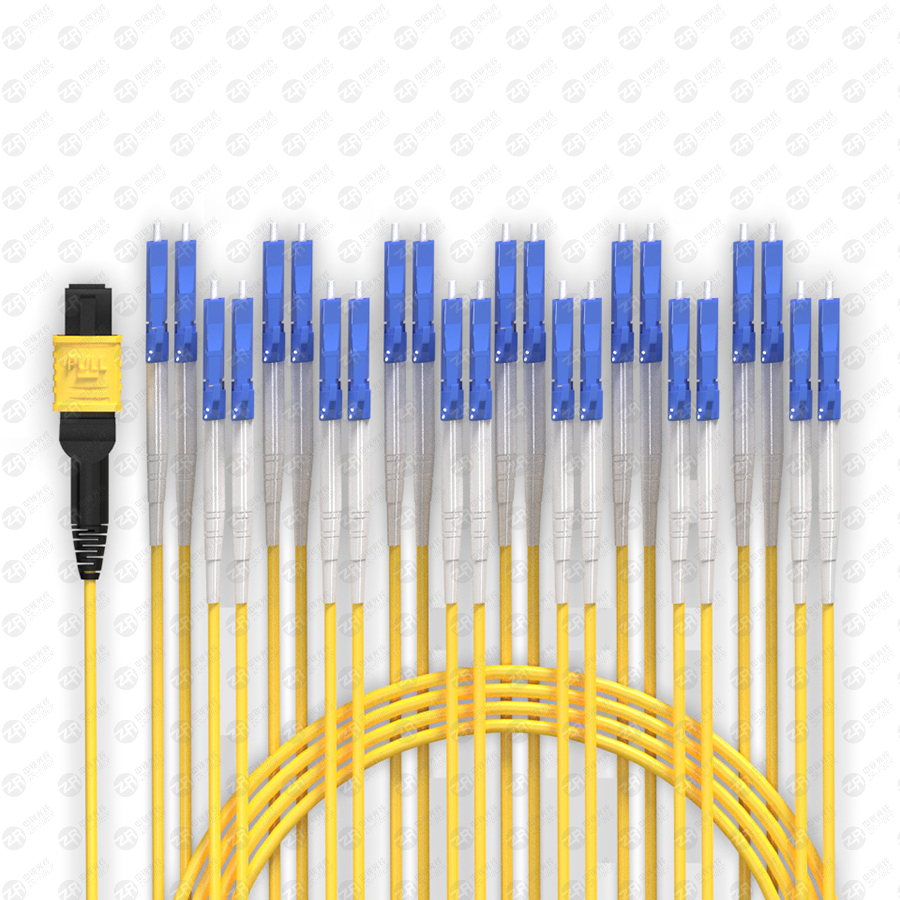

With the development of technology and the expansion of applications, optical fiber connectors have also developed rapidly. There are about 12 or more types of optical fiber connectors on the market now, each of which is developed to meet specific needs. Of course, there are also certain technical limitations. The current market trend is mainly towards an affordable, compact connector model that can support the greater transmission density required by new transmission distribution systems. As users have come to expect, the continued growth of the telecommunications industry has also driven the mass adoption of fiber optics, largely due to the burgeoning demand for fiber optic connectivity for various types of communications and entertainment services.

Terminal Considerations

Traditionally, fiber optic terminals are generally slower and more expensive, and have high requirements for equipment and technology. These factors should be considered when considering fiber terminations in singlemode cables. In some cases, we can choose some cables that are already terminated according to various fiber types.

In tailor-made applications, we can only select specific terminals, but the use of splicing tools can reduce the extended length of single-mode fiber field terminations, reducing the number of equipment required and the use of technology. For multimode fiber optic cables, the new splicing method uses a simple fiber cleavage method to assemble the cables into pre-designed connectors/cables. This method is very simple, but the fiber-to-fiber connector is butted, and a special optical gel is usually used at the connector to condense the fiber end.