The indoor dual-core sheathed optical cable access market shows a good development trend, but how to make the dual-core sheathed optical cable connector is a difficult problem that puzzles many novices. So, how to make the double-core optical cable connector? Let's go to find out together.

Indoor dual-core sheathed fiber optic cable

1. What is a leather cable

Leather cable is commonly known as indoor hanging wiring cable. With the domestic optical fiber access market showing a good momentum of development, optical fiber access has become a hot spot in the field of optical communications. In the optical fiber access project, the indoor wiring close to the user is the most complicated link. The bending performance and tensile performance of conventional indoor optical cables can no longer meet the needs of FTTH (fiber-to-the-home) indoor wiring.

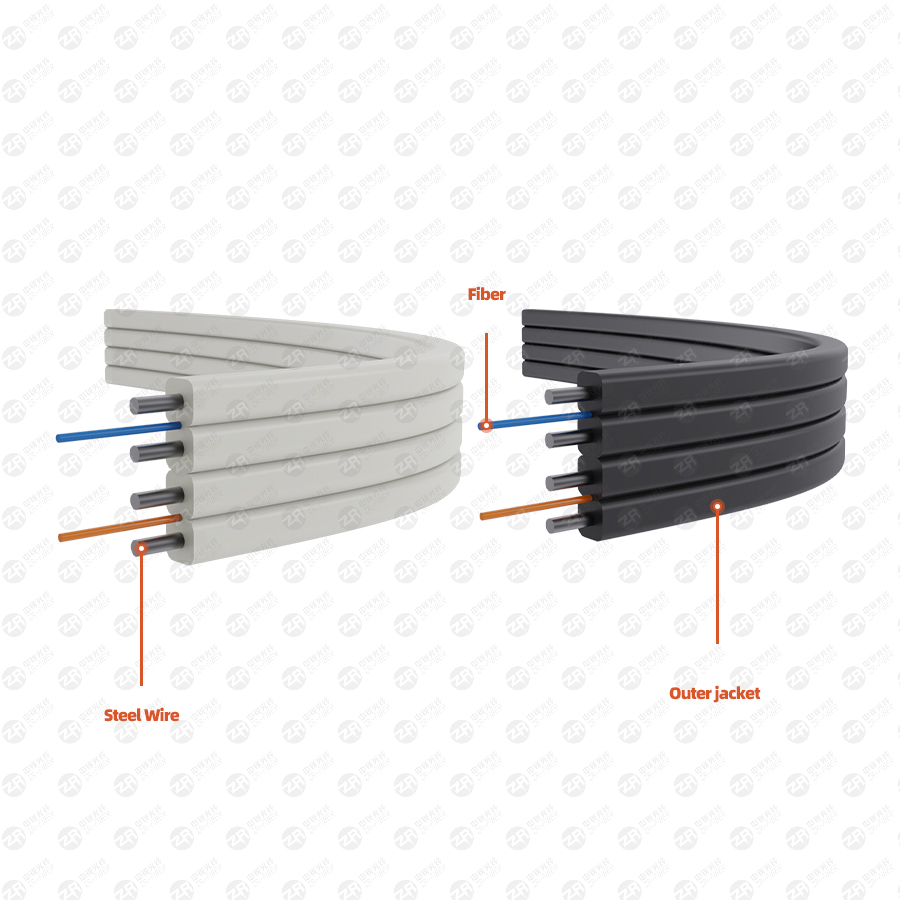

The dish-shaped drop optical fiber cable for access network (for indoor wiring) is to place the optical communication unit (optical fiber) in the center, and place two parallel non-metallic reinforcement members (FRP) or metal reinforcement members on both sides. It is sheathed with vinyl chloride (PVC) or low smoke halogen free material (LSZH, low smoke, halogen free, flame retardant).

The sheathed optical cable is mostly single-core or double-core structure, and can also be made into a four-core structure. The cross section is in a figure-8 shape. The reinforcement is located in the center of the two circles. Metal or non-metallic structure can be used. . The optical fiber in the leather cable adopts G.657 small bending radius optical fiber, which can be laid with a bending radius of 20mm.

Ordinary leather cable is a standard 8-shaped structure; two parallel strengthening cores, optical fiber in the middle; self-supporting cable adds a thick steel wire hanging wire to the structure of ordinary cable; in general, self-supporting cable The optical fiber cable is just one more steel wire, and nothing else has changed;

The structure of this kind of optical cable is different for each manufacturer. But they are generally not metal reinforced cores, such as butterfly-shaped leather cable. The shape of the cross section is like a butterfly, so it is called. The two sides are the leather wire and the inner part is the reinforcement, and the middle part is the optical fiber.

1. Butterfly optical cable is divided into indoor and indoor (indoor) and outdoor. The price of the two is quite different. The price of the outdoor type is about twice the price of the indoor type. The price factor should be considered when making a specific design plan. The ordinary optical cable (GYTA-G 652D) is still used outdoors, and the indoor butterfly optical cable is used indoors, and the two are transitioned through a fiber distribution box or a splice box.

2. The butterfly optical cable has the characteristics of small curvature radius, light weight, relatively good bending resistance, easy to fix, and easy to be terminated in the 86 terminal box.

3. Butterfly-shaped home optical cable has two forms: non-metallic reinforcing member and metal reinforcing member. Considering the factors of lightning protection and strong electric interference protection, non-metallic reinforcing member butterfly optical cable should be used indoors.

4. Indoor butterfly optical cable has 1 core, 2 core, 3 core, 4 core and other specifications. Residential users should choose single core cable for access butterfly cable; business users can access butterfly cable according to 2--4 Core cable design.

The large-scale use of leather cable in the FTTX project mainly adopts two connection methods: one is the cold splicing technology (physical splicing) of the optical cable based on the cold splicing, and the other is the hot-melting technology using the fusion splicer as a tool.

2. How to make a double-core optical fiber cable connector

Production of double-core sheathed optical cable connector:

The optical fiber cold splicer is used when the two pigtails are butted. The main component inside is a precise v-groove. After the two pigtails are pulled out, the cold splicer is used to realize the butt of the two pigtails. It is easier and faster to operate and saves time than welding with a welding machine.

It is used for optical fiber butt optical fiber or optical fiber docking pigtail, which is equivalent to making a joint, (fiber docking pigtail refers to the butt joint between the optical fiber and the core of the pigtail, not the pigtail head mentioned by the former), which is used for this kind of cold splicing. Something called a fiber optic cold splicer.

With the rapid development of FTTH fiber-to-the-home, the demand for optical fiber cold splices has also greatly increased.

Optical fiber quick connectors and optical fiber cold splices will play an irreplaceable role in FTTH access. The field termination technology of optical fiber quick connectors just solves this problem. The operation is convenient and fast without fusion splicing, and the connection cost is low, which truly realizes access anytime, anywhere. .

The above is all about how to make a double-core optical cable connector. I believe that after reading this article, you have a certain understanding of how to make a dual-core optical cable connector. In fact, it is not difficult to make a double-core leather cable connector. The key is to master certain skills. I hope that the above can give you some help.