1. How to lay the submarine optical cable

To put it simply, the laying of the submarine optical cable is to place the optical cable on the submarine cable laying ship, and then the ship slowly starts and sinks the optical cable into the seabed. If you want to talk about it in detail, the laying of optical cables mainly includes three stages of optical cable routing survey and cleaning, optical cable laying and burial protection.

First of all, fiber optic cable laying is usually done by a cable burying machine that digs the seabed. It is a bit like a plow used in ploughing fields. It is towed by a submarine fiber optic cable laying ship, and various commands are made through the working fiber optic cable.

Secondly, there are several rows of water spray holes at the bottom. During operation, each hole sprays a high-pressure water column to the seabed at the same time, and the seabed sediment is washed away to form an optical cable trench. Finally, there is a fairlead hole on the upper part of the device to guide the optical cable (optical cable) to the bottom of the optical cable trench.

2. What to do if the submarine optical cable fails

Submarine optical cables often fail, sometimes due to inadvertent damage from ships, sharks, etc., sometimes deliberate damage by enemy forces, and more often problems caused by earthquakes.

For example: Affected by the earthquake, a number of international submarine communication cables were interrupted, resulting in domestic Internet users unable to access foreign websites normally. Also under the influence of the earthquake, a number of submarine optical cables passing through the relevant sea areas failed.

Compared with laying optical cables, the difficulty of repairing optical cables continues to increase, because finding faulty optical cables with a diameter of less than 10 cm from the seabed as deep as hundreds of meters or even thousands of meters is like finding a needle in a haystack, and then reconnecting it after repairing. It is also very difficult.

Usually, the general submarine cable fault processing will go through 5 steps. First, use a spread spectrum time domain reflectometer to locate the approximate fault location. After that, the precise location of the damaged submarine optical cable is found by the diving robot, the fault location is cut off, and the remaining two ends are towed back to the repair ship for repair. Next, connect the two breakpoints of the damaged cable with a spare submarine cable and put it back on the seabed after testing.

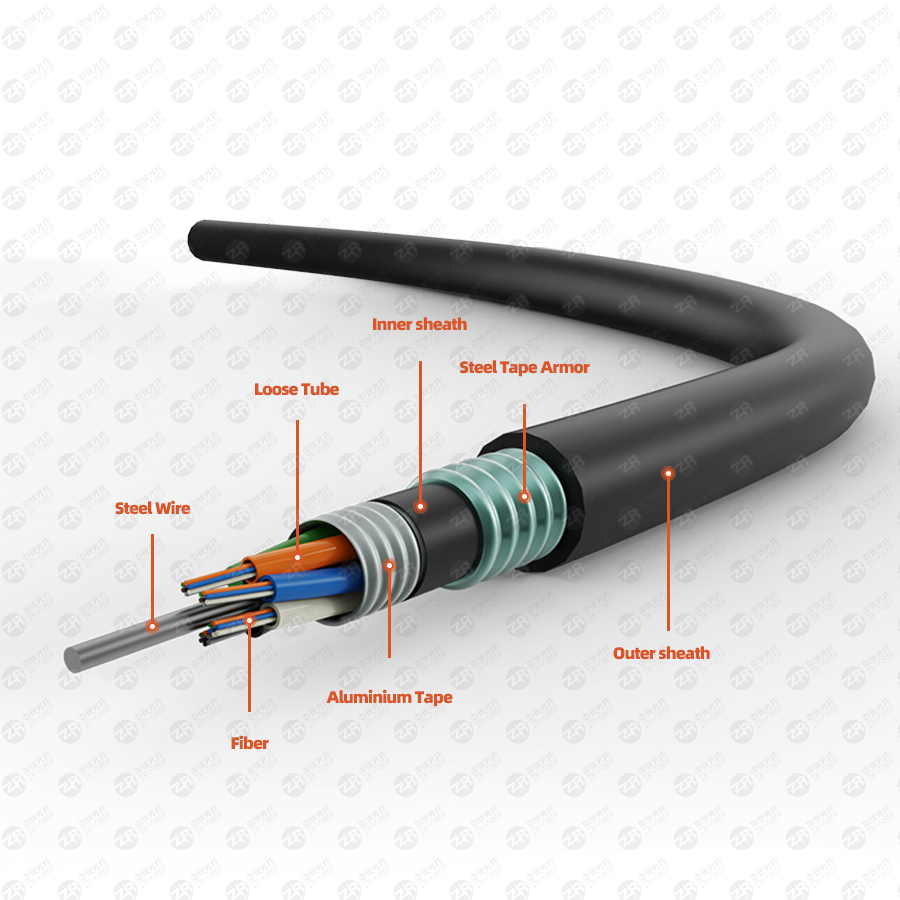

Regarding the relevant knowledge of submarine optical cables, I will talk about it here for you first, and finally I will give you a knowledge point. The basic structure of submarine optical cables is composed of polyethylene layer, polyester resin or asphalt layer, steel strand layer, aluminum Waterproof layers, polycarbonate layers, copper or aluminum pipes, paraffin, alkane layers, fiber optic bundles, etc. So its diameter is usually 69 mm, its weight is up to 10 kg per meter, and its design life is 25 years of continuous operation.