Optical fiber cable is manufactured to meet optical, mechanical or environmental performance specifications, it is a communication using one or more optical fibers placed in a sheath as the transmission medium and can be used individually or in groups cable assembly. The following introduces the basic knowledge about optical cables in the form of question and answer:

fiber optic cable

1. What are the common structures of optical cables?

The common optical cable structure of optical cable has two types: layered type and skeleton type.

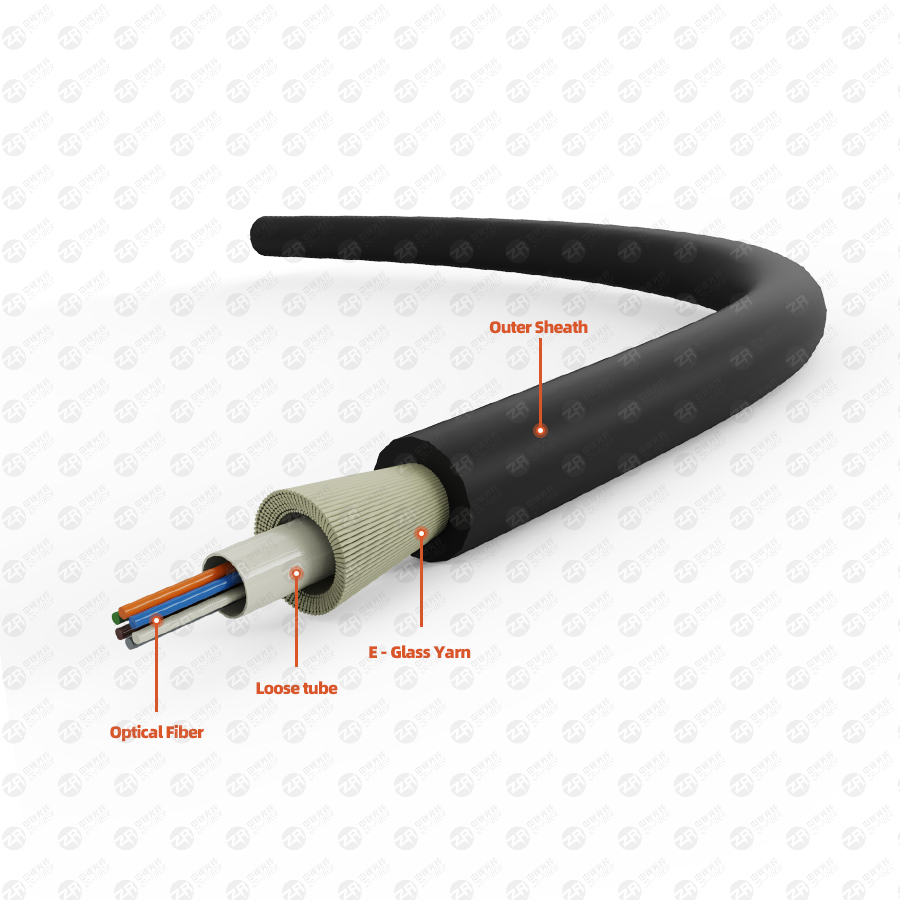

2. What is the main composition of the optical cable?

The optical cable is mainly composed of: fiber core, optical fiber ointment, sheath material, PBT (polybutylene terephthalate) and other materials.

3. What is the armor of the optical cable?

The armoring of optical cables refers to the protective elements (usually steel wires or steel tapes) used in special-purpose optical cables (such as submarine cables, etc.). The armor is attached to the inner jacket of the cable.

4. What material is used for the cable sheath?

The optical cable jacket or sheath is usually composed of polyethylene (PE) and polyvinyl chloride (PVC) materials, and its function is to protect the cable core from external influences.

5. What are the special optical cables used in power systems?

There are mainly three types of special optical cables used in power systems: ground wire composite optical cable (OPGW), wound optical cable (GWWOP), and self-supporting optical cable (ADSS).

Ground wire composite optical cable (OPGW), the optical fiber is placed in the power line of the steel clad aluminum stranded structure. The application of OPGW optical cable plays the dual function of ground wire and communication, and effectively improves the utilization rate of power towers.

Wrap-around fiber optic cable (GWWOP), which is wrapped or suspended from the ground wire where there is an existing transmission line.

Self-supporting optical cable (ADSS) has strong tensile capacity and can be directly hung between two power poles and towers, and its maximum span can reach 1000m.

6. What are the application structures of OPGW optical cables?

The application structure of OPGW optical cable mainly includes: structure of plastic tube layer + aluminum tube, central plastic tube + aluminum tube structure, aluminum skeleton structure, spiral aluminum tube structure, single-layer stainless steel tube structure, central stainless steel tube structure, stainless steel tube layer Stranded structure, composite stainless steel tube structure, central stainless steel tube structure, stainless steel tube layer twisted structure.

7. What is the main composition of the stranded wire outside the core of the OPGW optical cable?

The stranded wire outside the core of OPGW optical cable is mainly composed of AA wire (aluminum alloy wire) and AS wire (aluminum clad steel wire).

8. To choose the OPGW optical cable model, what are the technical conditions that should be met?

To select the OPGW cable model, the technical conditions that should be met are: 1) Nominal tensile strength (RTS) (kN) of the OPGW cable; 2) The number of fiber cores of the OPGW cable (SM); 3) Short circuit current (kA); 4 ) Short circuit time (s); 5) Temperature range (℃).

9. How is the bending degree of the optical cable limited?

The bending radius of the optical cable should not be less than 20 times the outer diameter of the optical cable, and not less than 30 times the outer diameter of the optical cable during construction (non-stationary state).

10. What should be paid attention to in ADSS optical cable project?

There are three key technologies in ADSS optical cable engineering: optical cable mechanical design, determination of suspension points and selection and installation of supporting hardware.

11. What are the main types of optical cable fittings?

Optical cable fittings refer to the hardware used to install optical cables, mainly including: tension clamps, suspension clamps, vibration isolators, etc.