The construction process of optical cable lines is complex, and the processes must be properly connected. Because the operation procedures are carried out according to scientific management methods, the implementation date of the project is planned, and the specific routing location, distance, and protection area are determined. It plays a role in ensuring that the construction tasks of the project can be completed on time with high quality. So, what are the standards for fiber optic cable laying projects?

Optical cable laying project

1. Routing retest of optical cable lines

1. According to the design requirements, determine the routing direction of the optical cable and select the laying method. (Mainly divided into urban areas, suburban areas and open areas by on-site investigation. Generally, the construction of urban and suburban areas is more complicated, and the open areas are relatively easier. Therefore, the project price is determined according to the relevant geographical environment.)

2. Check the distance from the hop to another terminal to provide the necessary data.

3. Check and approve the technical measures of obstacles such as roadblocks and river courses, and work out the possibility of specific implementation.

4. Carefully observe the topography and landforms, and preliminarily determine the environmental conditions for the location of the line joints.

2. Laying the optical cable

The laying of the line must be carried out according to the routing retest. If it must be changed in special circumstances, the approval of the competent department should be obtained in time.

According to the selected laying method and the difficulty of the project, the positions of the construction personnel shall be correctly allocated, and the responsibility shall be assigned to the person.

1. Aerial optical cable

(1) Requirements for overhead optical cable:

●Aerial optical cable mainly has two types: steel-strand supported type and self-supporting type. Our country basically adopts the steel-strand-supported structure, which is erected by hanging or bundling by means of poles.

●The distance between the poles of the overhead line is 25-40 meters in urban areas, 40-50 meters in suburban areas, and no more than 67 meters in other areas.

●The hanging wire of the aerial optical cable should use the galvanized steel strand with the specification of 7/2.2mm, and the 7/2.0mm or /1.8mm steel strand can be used when the light armored optical cable is used for hanging.

●The sag of the aerial optical cable should consider the elongation rate generated during the erection process and under the maximum load after erection.

●Aerial optical cable can be properly stretched on the pole.

●Put up poles according to the design requirements, lay down the hoisting line or use the original pole road for remediation to meet the specified requirements.

●The distance between the hooks of the optical cable hooks is required to be 50 cm, and the allowable deviation is not more than ±3 cm. The optical cable should be hanged evenly, the hook support plate is complete, and different sizes of hook models should be selected for the outer diameter of various optical cables.

⑵ optical cable hanging wire erection method:

●Adopt the guide pulley, that is, put the suspension wire into the pre-installed suspension wire groove along the line at the end of one terminal, install a large pulley at the other end of the pole, and use the wire take-up machine or hoist to carry out after changing the direction. The hanging wire is tightened.

●When laying the optical cable, a small guiding pulley should be installed every 20~30 meters, and the pulling rope should be passed through the pulley in sequence until it reaches the end of the optical cable to be pulled. Generally, the optical cable is pulled several times during construction.

●After the optical cable is pulled, hang the optical cable on the hanging line with hooks from one end or several ends at the same time, which is usually adopted (engineers can operate faster by scooter). Other methods can also be used. When hanging the line, if it is a long-distance trunk line, due to its certain distance, leave an appropriate excess coil to tie it on the pole road, so that the line is easier to recover in special circumstances. (3)Wall optical cable

●When there is no pole road for wall optical cable, choose factory or residential building for optical cable laying.

●Most of the wall optical cables are used in the construction of communication lines used in factories, mines, enterprises and living quarters.

●Its erection is basically the overhead of a pole road.

2. Pipeline cable

For the city ф90MM standard pipe hole, it can accommodate 3 3~4 inch plastic sub-pipes. The 1-inch sub-tube is suitable for optical cables with a diameter of less than 20MM, and suitable sub-tubes should be selected for other types of optical cables.

●The sub-pipe is easy to be twisted during the laying process. When the twist pitch is within 10 meters, the friction between the optical cable and the inner wall of the sub-pipe will increase, which will bring certain difficulties to the laying of the optical cable. Therefore, the laying of the plastic sub-pipe should be Avoid twisting.

●When laying the optical cable in the pipeline, the entrance and exit of the manhole should be turned, and the curve and the height difference of the pipeline manhole should be equipped with a guiding device to reduce the friction of the optical cable and reduce the pulling tension of the optical cable.

●A special tool "nylon rod" should be used in the optical cable pulling sub-pipe, which can be pulled by appropriate engineering and technical personnel in a row. After the optical cable is pulled, the remaining cables in each manhole shall be manually placed on the specified bracket. For future safety, hoses or PE hoses are generally used for protection, and they are rolled and fixed with cable ties. The end of the optical cable should be hung on the wall of the manhole after leaving a suitable length of coil. Do not immerse in water.

3. Buried optical cable

●For laying direct-buried optical cables, trenches must be dug first, and it is very important to achieve sufficient depth and uniform standards along the line according to different environments. The standard for digging trenches is generally 1.2 meters for ordinary soil, 1.0 meters for semi-stone, 0.8 meters for quicksand when crossing iron, and 1.2 meters for highways. When laying two or more optical cables in a trench, a distance of 5CM should be maintained between the optical cables. Steel pipes or rigid plastic pipes should be pre-buried in the sections where the road surface is often under pressure. When laying the optical cable, it should be laid in an "S" shape when it encounters special sections such as slopes, crossing iron, and highways.

Direct buried optical cable must take "two defenses" measures

⑴Lightning protection:

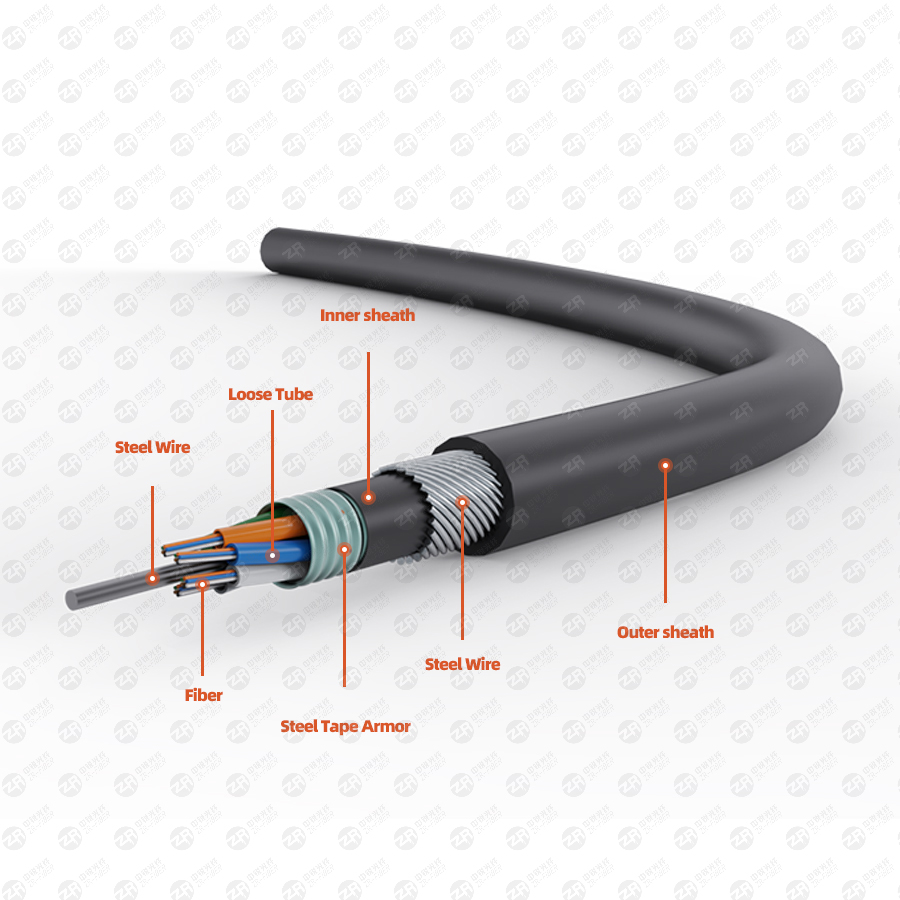

Most of the directly buried optical cables use metal parts such as strength members, moisture-proof layers and armoring layers, which are prone to lightning strikes, and communication is interrupted when the optical cable is seriously damaged.

Treatment measures: A. Intra-office grounding method B. System grounding method C. Laying shielded wires above the optical cable

(2) Anti-corrosion, anti-rat, etc.

The above is the analysis of the optical cable laying engineering standards that Xiaobian brings to you. I believe that you all know what the standards of the optical cable laying project are when you see it. I hope it can bring you some help.