As we all know, compared with copper cables, optical fibers are very fragile and easily damaged, especially in the process of optical fiber construction. Today, the editor will tell you what mistakes are often made in optical fiber construction and how to test optical fiber construction.

What are the common mistakes in optical fiber construction

Mistake 1: Not cleaning the fiber before splicing

Cleaning bare fibers is a very important step before fiber splicing. It should be noted that the bare fiber should be cleaned first, and then the bare fiber should be cut. In fact, nothing is cleaner than a freshly cleaved fiber endface, so never try to clean the fiber after cleaving, as this will contaminate the fiber endface. When cleaning bare fibers, it is strongly recommended that operators use fast-evaporating, non-flammable precision cleaning fluids.

Mistake #2: Using the Improper Cutting Tool

Whether the fiber end face is smooth or not has an important influence on the performance of the spliced or terminated fiber. In the past, fiber cleaving knives were used to manually cleave fibers, which required systematic training and skilled operators.

Now, with the development of technology, modern automatic cutting tools are very common in the market, which can improve the safety of the operator and protect the optical fiber. In general, the automatic cutting tool is an important tool to ensure the qualified fiber end face after cutting.

Mistake 3: Do not calibrate before fiber splicing

It is very important to calibrate the fusion splicer. In particular, the intensity or current intensity of the arc needs to be adjusted frequently to ensure that the size of the fusion joint is appropriate, so as to ensure that the mechanical strength of the fusion joint is strong enough and the optical performance is good enough.

This is especially important when working with air pressure changes or at high latitudes. In fact, the calibration work is very easy to do. For most fusion splicers, as long as the fiber is simply put on, it is like doing fusion splicing. However, when calibrating, you do not need to actually fuse, but go to the maintenance menu of the fusion splicer, select the option of arc calibration or arc backtest, and the fusion splicer will tell the operator how to calibrate step by step. After the calibration is complete, the fusion splicer will also remind you that the calibration is complete or if the entire system needs to be re-tested.

Mistake 4: Microbends in the fiber

Microbending of the optical fiber is generally caused by excessive pressure on the optical fiber. Microbending of the optical fiber can cause signal quality degradation, and this problem is difficult to detect with the naked eye unless an OTDR is used to check.

Mistake #5: Excessive bending of the fiber

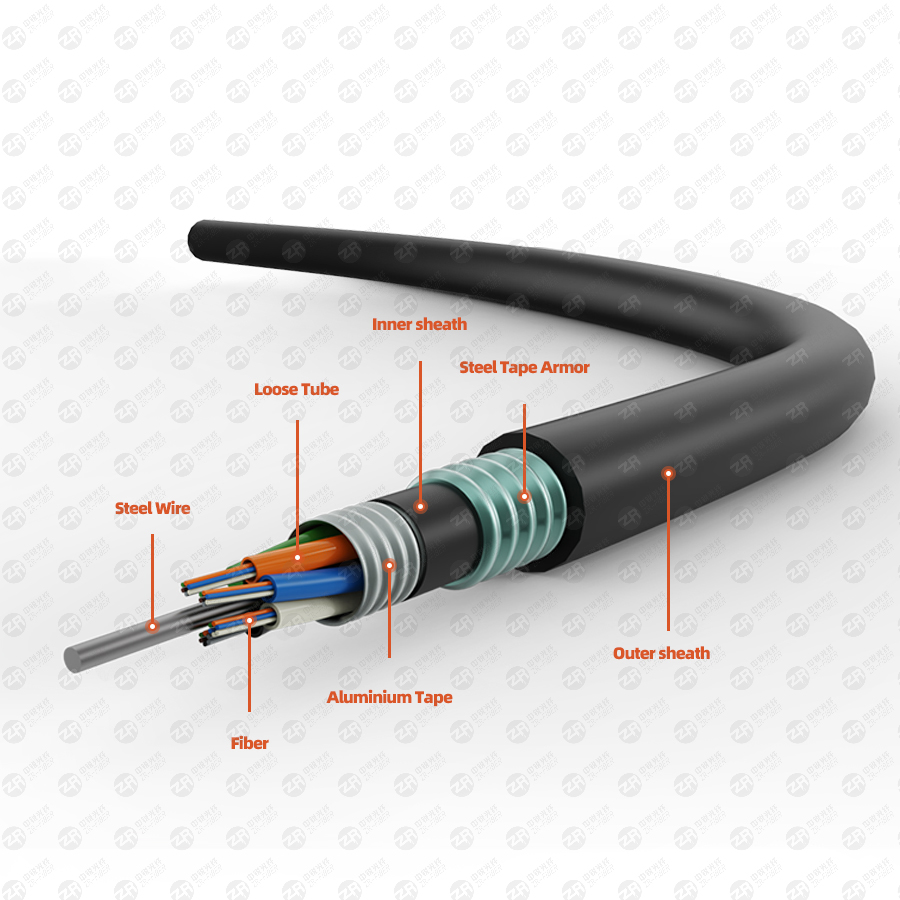

All optical cables have their own minimum bending radius. Therefore, we should pay attention not to exceed the minimum bending radius of the optical cable when constructing the optical cable, so as to avoid damage to the optical cable and the optical fibers in the sheath.

Mistake #6: Reusing wipes/cloths

Reusing wipes/cloths is a trivial act, because when a connector is cleaned with a wipe/cloth, the wipe/cloth is dirty and gets oil from your hands And the gray layer, if you use it to wipe other connectors, it will contaminate other connectors. Of course, if you really want to save money, you can buy the smallest size wipes/cloths.

Mistake 7: Not Inspecting and Cleaning Connector End Faces Before Installation

The end face of the connector is also a place that is easily polluted by dust and oil. Therefore, when installing the connector, we should check and clean the end face of the fiber optic connector. The cost of a ferrule end-face detector is less than the cost of two on-site maintenance and construction. Are you willing to spend a little money to do a cleaning inspection in advance or repair it afterwards or at a large price?

How to Check Fiber Construction

1. Choose optical cables with various characteristics according to the construction environment. If the construction environment is overhead, the optical cable is GYXTW type; if it is an underground pipeline, choose YSTS or GYTA type; if it is directly buried, choose GYTA53 type; in water, choose submarine Optical cables; smart buildings should choose indoor flexible optical cables; the number of cores should be determined according to the needs of users (generally 2 cores should be reserved for backup).

2. The guiding ideology of optical cable wiring in the local area network: it is required to be concealed and beautiful, because most of the customers are schools, enterprises, government buildings, etc., and the structure of each building cannot be broken, and the existing space is used to avoid power lines and other The necessary and effective protection of the optical cable under the on-site conditions; investigate the site together with the person in charge of Party A, including the routing route and determine the optical fiber route and length after obtaining the approval of Party A.

3. Optical cable construction, specifically divided into wiring, optical fiber fusion, and testing.

(1) The wiring is organized and completed by professional construction personnel. The problems that should be paid attention to in the wiring: a, when the length of the optical cable is only a few hundred meters, it must be destroyed, otherwise the optical cable will not be straight and not beautiful; b, the corners cannot be folded into Less than or equal to 90 degrees, so as not to cause damage to the fiber core; c, the two ends of the optical cable should be marked, especially when the number of optical cable segments is large, the marking system of the wiring should follow the TIA-606 standard, and the marking must have a warranty period of more than ten years; d, When a cable has excess fiber at both ends, it should be cut to the required length, not rolled and bundled. E, in the wiring, there should be no hard object impact and heavy object extrusion;

(2) Optical fiber fusion splicing is an important part of optical fiber construction, and it is also the most critical part of controlling loss; first, it is necessary to choose a good optical fiber fusion splicer and testing equipment; the grinding used in the market has been gradually eliminated. Second, there must be professional and experienced operators for fine welding.

Optical fiber link loss mainly comes from the following four aspects: intrinsic, the characteristics of the optical cable itself, the loss is 0.34db/KM; fusion, optical fiber fusion telecommunication published standard is below 0.3db; wiring, the quality of wiring engineering will also affect the optical fiber The light propagates in the form of a sine wave, and the degree of bending will directly affect the dispersion of the light, causing the loss to increase; for insertion loss, after the fiber termination is completed, it needs to be connected with fiber jumpers and couplers. During this insertion process , the tightness of each device will directly affect the link loss.

(3) Optical fiber link test and document. There are two types of optical fiber testers, one is an optical time domain reflectometer (which is what we usually call OTDR) for measuring long distances (more than 1 km), and the other is an optical power meter for short distances. The application in the local area network is more common. The results of the fiber test must meet the following standards: 1000M link loss must be below 3.2db; 100M link loss must be below 13db. If the above requirements are not met, the network speed will be affected, such as slow download, packet loss, intermittent, fast and slow.

The above are the common mistakes in optical fiber construction and how to inspect the entire content of optical fiber construction. If you do not pay attention when inspecting optical fiber construction or if you do not pay attention during optical fiber construction, it may cause network failures. However, In fact, as long as the network construction personnel strictly follow the standard procedures, with a little care, these problems can be well avoided.