It can be a daunting task for anyone running fiber from indoor to outdoor and building their own custom fiber network. This conundrum is a common thread for fiber engineers on outdoor specification projects. The composition of indoor/outdoor loose tube cables is better suited to handle the tension caused by fluctuating temperature and humidity levels. The water-blocking yarn in an optical fiber expands, absorbs excess moisture and protects the fiber core, while meeting national fire code standards; however, as fire ratings vary worldwide, we offer options for different grades.

Loose Tube Cable

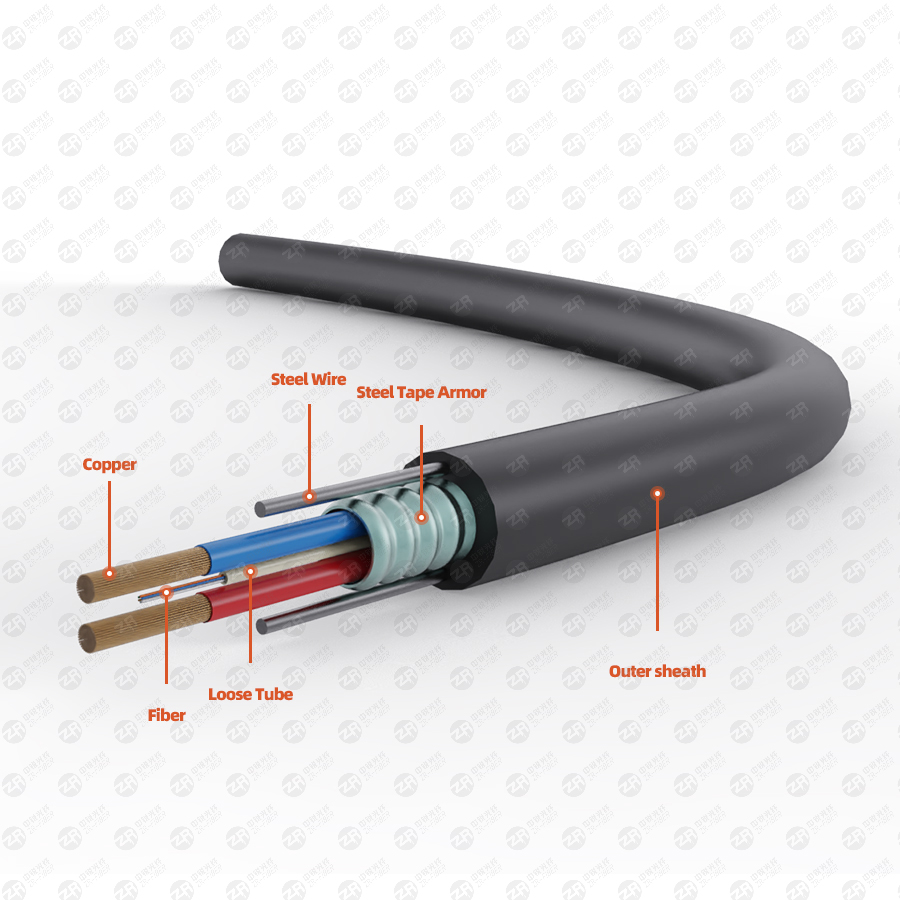

Loose tube fiber optic cables are manufactured with 1 to 6 subunits, water blocking yarn, aramid yarn and fire rated PVC outer jacket. To further strengthen the cable, there is an option to add a central strength member and waterproof tape, which can be used for 72 fibers. In addition, each subunit consists of 12 colored glass fibers, absorbent yarn wrapped in a 3mm diameter PVC jacket; the subunits can be color coded or numbered sequentially. All component materials are compliant.

Riser dry loose tube cable

The riser dry loose tube cable has similar specifications compared to the waterproof dry loose tube cable, only the riser dry loose tube cable has the waterproof rated material. The riser dry loose fiber optic cable is manufactured with 1 to 6 subunits, water blocking yarn, aramid yarn and PVC outer jacket with waterproof rating grade. Optionally add excipients. Water-blocking tape is also available for 72-fiber fibers. Each subunit consists of 12 coloured glass fibers and absorbent yarn wrapped in a 3mm diameter PVC jacket; the subunits have the opportunity to be sequentially numbered or color coded according to specific application requirements. All component materials are also compliant.

OSP dry loose tube cable

OSP loose tube cables are designed to withstand the harshest outdoor environments, including direct buried applications. This dry loose tube fiber optic cable consists of 1 to 6 subunits, water blocking yarn, dielectric strength material, aramid tear line and PVC outer jacket. Each subunit contains 12 colored glass fibers and water-swellable yarns with a 3mm diameter PVC jacket. With a variety of strand counts ranging from 12 to 144, Croft can help you find the right OSP cable for any application.