Fiber optic cable is a high-capacity transmission cable, and its quality and characteristics degrade when the cable is subjected to excessive tensile force or short bend radii. Take many precautions. If precautions are not taken during the cable pulling process, it may result in partial cable breakage or high loss.

Optical cable installation

Typically, in access networks, fiber optic cables are typically installed manually in a conventional manner. Usually installed every 300 meters, the fiber optic cable must pass through all MH/HH. According to the company's instructions, 10 to 20 meters of fiber optic cable loops are also required in each MH/HH. Failure to take precautions when unplugging cables in this type of network increases the likelihood of cable twisting and high losses. .

Precautions during fiber optic cable laying

In order to control the number of joints, the length section may be as long as 6000 meters. This will lead to many through manholes and the possibility of a two-way fractional pull. If excessive pulling force is applied to the cable during the cable pulling process, a brief bend or rupture of the inner tube may occur.

Fiber optic cables are not as strong as copper fiber optic cables, so extra care must be taken during handling, storage, and placement. Avoid sharp bending, kinking, crushing or excessive tension. These will destroy the glass fibers, and in severe cases, the fiber optic cable will need to be replaced.

During placement or storage, do not allow the vehicle to run over the fiber optic cable. Some technicians don't pay attention when pulling fiber optic cables and spreading tangles on the side of the road, and fiber optic cables are often crushed by cars, you have to pay attention during your work.

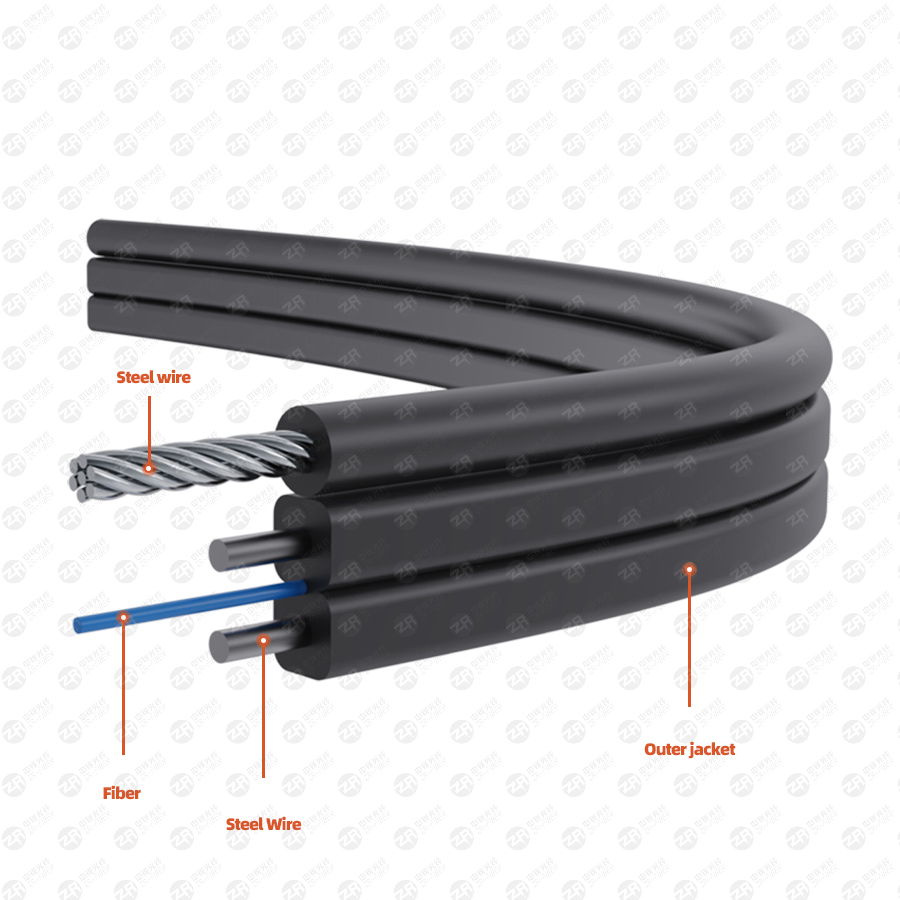

When laying out fiber optic cables in advance, you must check that the spools and fiber optic cables have not been damaged during shipping. To match by specification, the cable types, manufacturers, and lengths printed on the jacket and reel labels match each other.

Prolonged exposure to solar radiation can degrade the transmission characteristics of the fiber. Do not store optical cables in direct sunlight. It is best to store fiber optic cables indoors, away from dry locations for venue events.

cable handling

To prevent eye or personal injury, you must wear safety glasses when trimming the strength parts of the fiber optic cable. Hold the end of the strength piece with pliers to keep it from flying.

Gloves should be worn when handling cable strength components. Under no circumstances should splicing operations be performed on fiber optic cables without the technician satisfactorily completing an approved training course.

An unterminated fiber emits radiation if the fiber end is coupled to a working laser or light-emitting diode. Do not use optical instruments to look at the fiber end of the fiber optic cable until you have determined that the fiber is disconnected from the laser's laser. To prevent damage to the fiber, do not bend the optical fiber or cable to a radius less than twenty times the outer diameter of the cable. Safety glasses should always be worn when performing the splicing process of fiber optic cables.

All of the above considerations must be kept in mind when installing fiber optic cables. Life is more precious than work. During the installation of fiber optic cables, your utmost attention is required. Pay attention to the bend radius of the fiber optic cable. Sharp bends and kinks are not excluded. Never use an optical instrument to look at the fiber end of the fiber optic cable until you have determined that the fiber is disconnected from the laser of the LED light source.