As we all know, we will use fiber optic cable as the transmission medium for long-distance data transmission, because it has the characteristics of reliable function, high quality, fast speed, low line loss, and long transmission interval. Because it is a long-distance transmission, the optical cable on land is generally required to have a safe operation period of more than 20 years, while the submarine optical cable system requires a higher safe operation period of more than 25 years.

Therefore, how to correctly use optical cables in optical fiber wiring and how to extend the life of optical fiber cables are all issues that everyone is very concerned about. Next, let's talk about how to extend the service life of fiber optic cables from the perspective of the structure of the fiber optic cable.

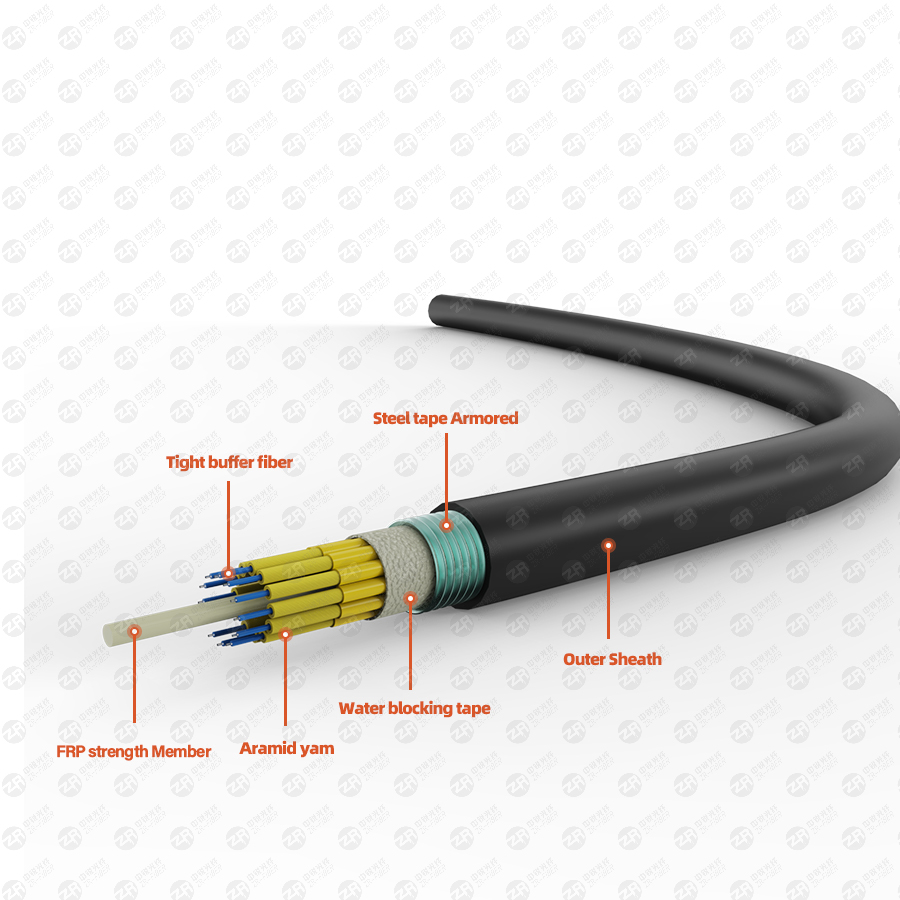

fiber optic cable

There are three major factors that affect the service life of optical fiber cables: 1. The stress left over from the unreasonable laying of the optical cable acts for a long time; 2. The existence and expansion of micro-cracks on the surface of the optical fiber; 3. The water and water vapor molecules in the atmospheric environment affect the surface of the optical fiber. erosion, etc.

Because of the above reasons, the mechanical strength of the optical fiber based on silica glass gradually decreases, the attenuation gradually increases, and finally the optical fiber is cracked, and the optical fiber cable can no longer be used.

When the fiber is in a vacuum environment, because there is no water molecule, stress corrosion will not occur. The fatigue parameter n is the maximum value, and the fiber also has the highest strength. The strength at this time is the inert strength of the fiber, which is called Si . There is a relationship between the service life ts of the optical fiber in the operating environment and the stress σ it accepts and the inert strength Si of the fiber: lgts=-nlgσ+lgB+(n-2)lgSi In the above formula, the latter two are both Therefore, when the received stress σ is constant, the service life ts of the fiber is only related to the value of the fatigue parameter n of the fiber. The larger the value of n, the longer the fiber life ts.

Ways to extend the service life of fiber optic cables:

1. Improve the static fatigue parameter n of the optical fiber to improve the service life of the optical fiber. Therefore, when making optical fibers, people try to isolate the quartz fiber itself from the atmospheric environment, so that it is not affected by the atmospheric environment, and try to change the n value from the environmental data parameters to the parameters of the optical fiber data itself, so as to make the The value of n becomes very large, resulting in the "sealing coating technology" on the surface of the optical fiber.

In the past ten years, the use of "sealing and coating technology" to make optical fibers has made great progress. Coating materials are extended from metals to metal oxides, inorganic carbides, inorganic nitrides, carbides, oxynitrides and CVD-deposited amorphous carbon. The coating structure has been developed from a single metal coating to a composite coating structure combining a sealing coating and an organic coating, which makes the optical fiber more valuable for practical use, and the optical function, mechanical function and anti-fatigue function of the fiber have improved.

2. When the fatigue parameter n is kept constant, the fiber life ts is only related to the received stress σ. Therefore, reducing the stress received by the fiber is a way to improve the service life of the fiber. When people make optical fibers, a compressive stress is formed on the surface of the optical fiber to resist the tensile stress received, so that the tensile stress is reduced as little as possible, thus producing the compressive stress cladding technology to make optical fibers.

To sum up, we can know that in the process of making fiber optic cables, we should pay attention to moisture and water resistance, reduce residual stress, and each raw material for making fiber optic cables must have a service life of more than 30 years, and high-stability physical properties. function and chemical function. As long as the quality of each production process is strictly controlled, the service life of the fiber optic cable can be extended.