As we all know, optical network systems also need to couple, branch and distribute optical signals, so this requires fiber couplers to achieve. So, what is a fiber optic coupler, and what are the principles and uses of fiber optic couplers?

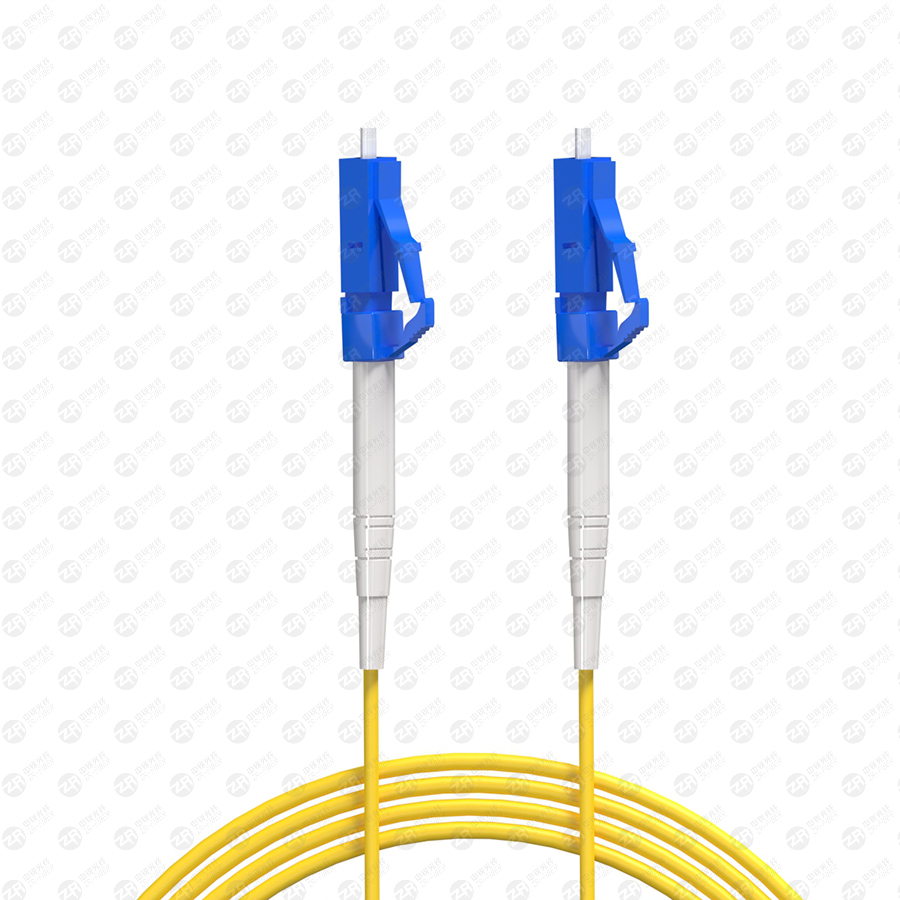

Fiber optic couplers are also known as fiber optic adapters, also known as fiber optic flanges. It is a device for detachable (removable) connection between optical fibers. It precisely butts the two end faces of the optical fiber, so that the light energy output from the transmitting fiber is coupled to the receiving fiber to the greatest extent, and the interference to the system is minimized by intervening in the optical link.

Principle of Fiber Coupler

It can be divided into two types: fused cone type and planar waveguide type. The fused cone type product is formed by splicing two or more optical fibers on the side; the planar waveguide type is a miniature optical component type product. Alternatively, an optical waveguide is formed on a semiconductor substrate to realize the branch distribution function.

The two spectroscopic principles are similar. They can achieve branches of different sizes by changing the evanescent field coupling (coupling degree, coupling length) between fibers and changing the fiber radius. Conversely, multiple optical signals can be combined into one signal. called a synthesizer. Fused-taper fiber couplers have become the mainstream manufacturing technology in the market due to their advantages of simple manufacturing method, low price, easy connection with external optical fibers, resistance to mechanical vibration and temperature changes.

The melting cone method is to disturb the two (or more than two) optical fibers from which the coating is removed in a certain way, melt under high temperature heating, and stretch to both sides at the same time, and finally form a double-cone heating zone. Using a special waveguide structure, different splitting ratios can be obtained by controlling the twist angle and stretching length of the fiber.

Finally, the cone area is cured with curing glue on the quartz substrate, and inserted into the stainless steel copper tube, which is the beam splitter. In this production process, since the thermal expansion coefficient of the cured adhesive is inconsistent with that of the quartz substrate and the stainless steel tube, when the ambient temperature changes, the degree of thermal expansion and contraction is inconsistent. This situation is likely to cause damage to the optical splitter, especially the optical splitter. The situation is even worse in the wild, which is the main reason why the light branches are easily damaged. For the production of multi-channel splitters, multiple two splitters can be used.

fiber optic coupler

Through today's introduction, I believe that everyone has a certain understanding of the principle of fiber optic couplers. If you want to know more about ZR fiber optic couplers, welcome customers to come to consult.

https://www.ductcable.com/cordSearch?patchTopType=3&subType=1