As a high-bandwidth, high-security data transmission medium, optical fiber is widely used in various large and medium-sized networks. Due to the high cost of cables and equipment, optical fibers are mostly only used for network backbones, that is, for system wiring of vertical backbone subsystems and building group subsystems to realize connections between buildings and floors. A horizontal wiring subsystem with high requirements for speed and security.

Optical fiber wiring scheme 1: wiring system and optical fiber cable

In the structured cabling system, optical fiber not only supports FDDI trunk, 1000Base-FX trunk, 100Base-FX to desktop, ATM trunk ATM to desktop, but also CATV/CCTV and fiber-to-the-desktop (FTTD), so it is common with copper cable. Become the protagonist in structured cabling.

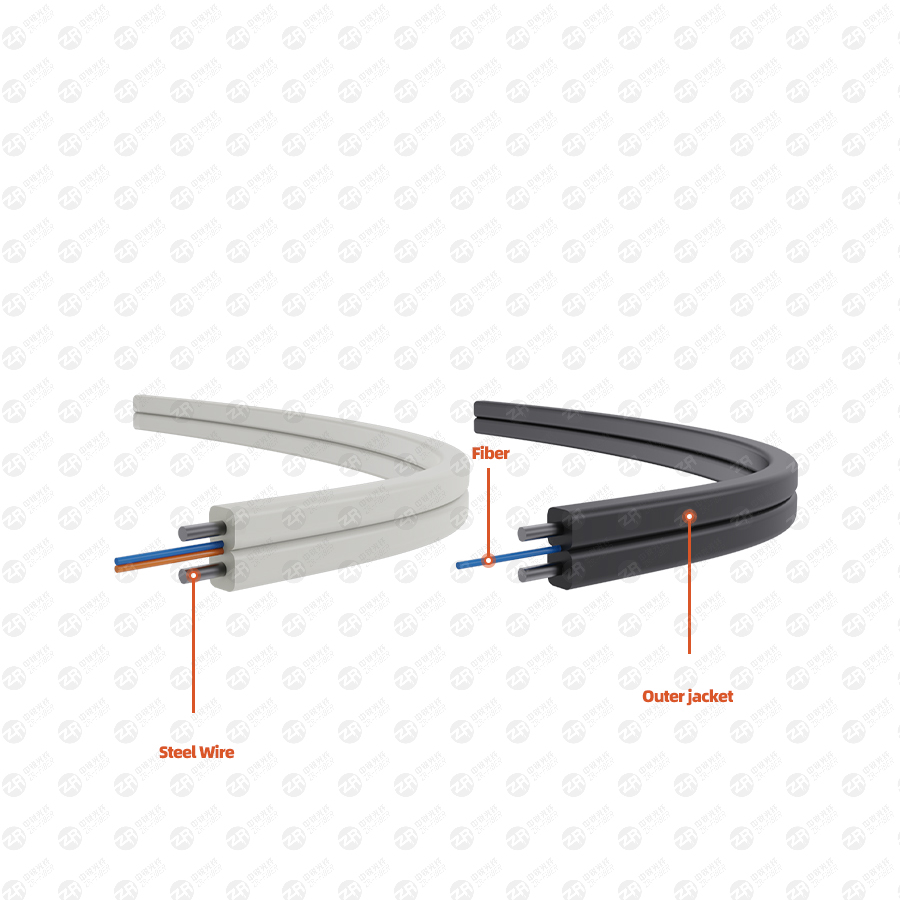

According to the structure of the optical fiber, it can be divided into ordinary optical fiber cable and optical fiber ribbon cable. As the backbone loop in the optical fiber access network, using ordinary optical cable laying will not only occupy valuable pipeline resources, but also re-lay optical cables on the original lines will cause waste in the cost of optical cable procurement and line laying. Considering the one-time cost of repeatedly laying cables and the ability to lease fiber bandwidth in the future, and to avoid pulling multiple cables in parallel to optimize an overcrowded duct system, it is reasonable to control the outer diameter of cables containing hundreds of fibers to a certain value. In order to facilitate the laying of optical cables within the range, the most ideal method is to use the design of optical fiber ribbons.

Compared with ordinary layer-stranded optical cables, optical fiber ribbon cables have many advantages that are more suitable for access networks. Optical fiber ribbon cables are more suitable for vertical backbone subsystems and building cluster subsystems of large networks. Of course, if the horizontal wiring also uses a large number of optical cables, then the optical fiber ribbon cable should also be the first choice.

The internationally popular wiring standards EIA/TIA-568A and ISO/IECIS11801 recommend the use of 62.5/125μm multimode optical cable, 50/125μm multimode optical cable and 8.3/125μm multimode optical cable. Optical fibers and optical cables are widely used in the integrated wiring system of modern buildings. Optical fibers are divided into single-mode optical fibers and multi-mode optical fibers. Single-mode optical fibers and multi-mode optical fibers can be easily distinguished from the size of the core. It is suitable for optical fibers to desktops, connecting to transmission equipment, and making optical fiber jumpers. Applies to management subsystems, inter-device subsystems, and workspace subsystems.

Optical fiber cabling scheme 2: Implement fiber optic cable wiring

Optical fiber cabling scheme

Because both ends of each optical cable must be polished, electric barbecue and other processes to ensure normal use, and the price of such process equipment is also very expensive, so the production of optical cable wiring and optical jumpers is currently only done by some professional companies. Complete, generally small companies and computer users cannot complete the construction of optical fiber networks, but we can check the quality of the construction according to the following contents. The general requirements for fiber optic cable laying are as follows:

Minimum radius of curvature of fiber optic cable

The minimum allowable curvature radius of the optical cable shall not be less than 20 times the outer diameter of the optical cable during construction, and shall not be less than 15 times the outer diameter of the optical cable after construction.

Tension and side pressure of fiber optic cable

The tension and side pressure when laying the optical cable shall meet the requirements in the following table. It is required that the traction force for laying the optical cable should not exceed 80% of the allowable tension of the optical cable, and the instantaneous maximum traction force should not be greater than the allowable tension of the optical cable. The main pulling force should be applied to the strengthening member of the optical cable, and the optical fiber cannot bear the pulling force directly.

Optical fiber wiring scheme three: laying of indoor optical fibers

Indoor optical cables are mainly used in the laying of horizontal subsystems and vertical backbone subsystems. The laying of cables for the horizontal subsystem is very similar to twisted pair, except that due to the poorer tensile properties of the cables, more care should be taken when pulling and the radius of curvature is larger. The vertical backbone subsystem optical cable is used to connect the equipment room to the wiring room on each floor, and is generally installed in the cable shaft or the rising room.

In order to prevent sagging or slipping, the optical cable must be securely fastened at the top, bottom and middle of the channel on each floor. Usually, nylon ties or steel clips can be used for effective fixation. Finally, oil hemp plugging materials are also used to block and seal all the grooves and the gaps of the pipe holes through which the optical cables pass through each floor in the building, and fire prevention measures such as blocking fire-proof materials should be taken to achieve the effect of moisture and fire prevention.

When laying the optical cable, an appropriate length should be reserved according to the design requirements. Generally, 5m-10m should be reserved at the equipment end, and it should be appropriately extended if there are special requirements.

Optical fiber wiring scheme four: laying of outdoor optical fibers

Outdoor optical cables are mainly used for wiring of building complex subsystems. When implementing the wiring of building complex subsystems, pipeline optical cables should be the first choice, and direct buried optical cables or overhead optical cables should be used only in the case of unavoidable circumstances.

1. Laying of pipeline optical cable

① Clean and test. Before laying the optical cable, the pipe holes should be cleaned and tested one by one. When cleaning, use a special cleaning tool, and use a test stick for test pass inspection after cleaning. The inner diameter of the plastic sub-tube should be 1.5 times the outer diameter of the optical cable. When more than two sub-pipes are placed in a cement pipe hole, the equivalent total outer diameter of the sub-pipes should be less than 85% of the inner diameter of the pipe hole.

② Lay out the plastic sub-pipe. When wearing more than two plastic sub-pipes, if the pipes are of different colors, the ends may not be marked. If the pipes are the same color or no color, they should be marked separately at their ends.

③ Optical cable traction. Generally, the length of one-time pulling of optical cable should be less than 1000m. When this distance is exceeded, segment traction should be adopted or auxiliary traction should be added in the middle position to reduce cable tension and improve construction efficiency. In order to protect the surface of the optical cable from damage during the pulling process, when the optical cable penetrates the pipe hole, the pipe bend or intersects with other obstacles, protective measures such as guiding device or bell mouth protection tube should be adopted.

④ Reserve a margin. After the optical cable is laid, the optical cable should be placed on the specified pallet one by one in the manhole or hand hole, and an appropriate margin should be left to prevent the optical cable from being too tight. When the optical cable in the manhole or hand hole needs to be connected, the reserved length should meet the minimum value specified in the table.

⑤ Joint handling. The optical cable shall not have a joint in the pipe hole in the middle of the pipe. When the optical cable does not have a connector in the manhole, the optical cable is required to be bent and placed on the optical cable support plate for fixing and binding, and must not pass directly in the middle of the manhole, otherwise it will not only affect the construction and maintenance, but also easily lead to damage to the optical cable. When the optical cable has joints, it should be protected by pipes such as serpentine hoses or soft plastic pipes, and placed on the pallet to be fixed and bound.