In the current general optical fiber cabling network, because the technology and quality of the optical fibers used in the wiring are generally stable, the characteristics of optical cables composed of optical fibers and various optical fiber connectors, jumpers, pigtails and other components are relatively stable. And in the actual use of wiring, they are relatively fixed, so most of the reasons that may actually affect the stability of the optical fiber network are concentrated in the optical fiber connection technology. discuss:

Fiber optic technology pre-connected fiber optic cables

1. Splicing method: Optical fiber fusion splicing is a connection method that is widely used at present. Relatively speaking, fusion splicing is a method with high success rate and connection quality, but it should also be noted that the joint after fusion splicing is relatively easy. One of the main factors for damage or failure.

Since the maintenance operation of the equipment is necessary in the process of use and maintenance, its safety is a problem that we must consider. Under normal circumstances, splicing can obtain a small connection loss, generally below 0.2dB, but the return loss is not easy to control, and in the process of fiber splicing, there are many external factors that affect the quality of splicing, such as environmental conditions ( Including temperature, wind, dust, etc.), operation proficiency (including preparation of fiber end face, aging of electrode rods), optical fiber matching (including optical fiber, pigtail type matching, optical fiber manufacturer matching), etc.

If the multi-core ribbon fiber connectors such as MTP, which are not used much in China at present, are used, the ribbon fiber fusion splicer cannot avoid the reality that the individual fiber loss is too large during the fusion process; moreover, experience tells us that the reality of fusion The loss value can only be obtained by testing. In the case of a large number of fiber cores, it is easy to damage the completed ones. In the testing stage, if the test results are not satisfactory or do not meet the standards, they must be re-selected and then reworked; After the network has been used, if the network cabinet or terminal needs to move the location, the optical fiber link must be interrupted, and the new location must be re-spliced, etc.; all the above possible occurrences make us pay a lot of labor and Be extra careful with fiber optic safety.

2. The method of cold splicing or on-site grinding of optical fiber connectors: Anyone who has been engaged in factory manufacturing and production of optical fiber products should know this very well. On-site grinding and factory manufacturing are two completely different methods that are incomparable. The factory adopts It is a five-step grinding process from coarse to fine by a special grinding machine. It is impossible to adjust the pressure and maintain a consistent manual grinding on site. Perhaps in the traditional low-speed network in the past, even if the insertion loss and return loss exceeds the standard, the connection is unstable, etc., it may be acceptable for network applications, because the optical fiber has enough surplus to absorb the impact of these factors.

However, in today's increasingly high-performance network, many indicators and parameters are extremely sensitive, because the link fails to meet the design requirements or is time-consuming and labor-intensive, which makes designers or constructors troubled, and the loss exceeds the network design. Requirements, test failures, etc. occur from time to time.

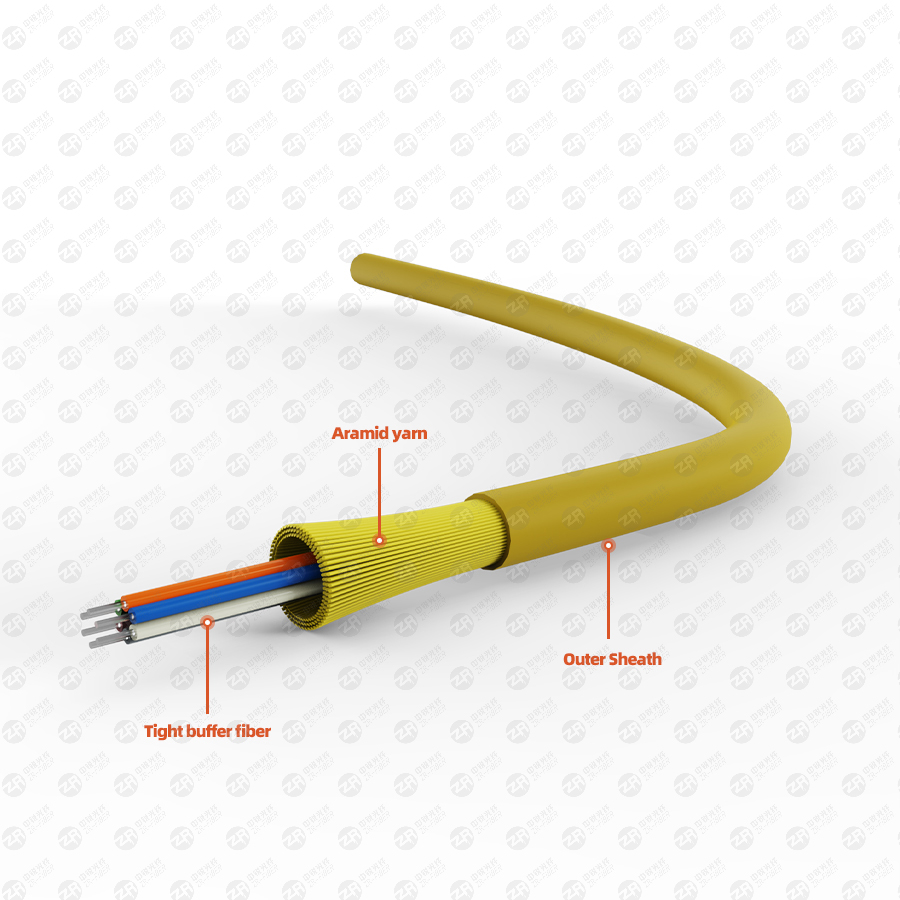

As a result, there are consequences such as delays in construction schedules, design changes or re-planning. According to the actual situation of the above design and construction, in order to solve the problems that may be encountered in the optical fiber connection, make the design, construction, maintenance and use more reliable and stable, and the system change is easier to operate, the pre-connection technology can be selected according to the actual needs of the site. PE or LSZH indoor or outdoor optical cables with connectors pre-terminated at the ends. The pre-connected optical cables use special branch components to turn the bare optical fibers in the optical cables into φ3.0 or φ2.0 optical cables that can withstand tension and compression at the output end. , it minimizes the damage or safety impact that various uncertain factors may cause to the optical fiber link in the design, construction and use of the optical fiber network, and fully guarantees the system safety and meets the design requirements.

Compared with the traditional optical fiber terminal methods, the pre-connection technology adopts the optical fiber straight-through method, that is, the optical fiber has no connection point. According to the customer's requirements, the products are customized by the factory, and the grinding process is carried out in standard procedures. All technical indicators comply with IEC, TIA and related standards. At this point, the technical indicators far exceed the connectors grounded on site.

At the same time, the structure of the optical cable is also different from the indoor soft optical cable commonly used in China. In order to ensure that the optical cable has sufficient mechanical properties, its structure is a central bundle of 2 cores to 144 cores. The oil-filled structure of the optical cable also ensures the environmental and water-blocking characteristics of the optical cable. In the output part of the optical cable, there is no welding or other mechanical connection methods, which eliminates the possible adverse consequences caused by the existence of joints. Any fiber optic cable products that may add factors to make the design or construction of the network more controllable.

In addition, because the pre-connection adopts special optical cable branch components, the plug-in structure can firmly fix the optical cable on the special rack to ensure that the 50kg tension distribution box will not be deformed. At the same time, the rectangular card interface can prevent the optical cable during use. The stress is released, so that the optical fiber link between the connectors at both ends is always in a free and slack state, avoiding the performance of the optical fiber due to the extrusion, stretching or twisting of the cable sheath, and ensuring the safety of the optical fiber network and the owner's investment to the greatest extent. sex.

From the above structural characteristics, we can see that the type of optical fiber connector used for pre-installation is variable, mainly according to the design and customer needs. It eliminates the influence of various unfavorable factors in multi-core fiber connection, allowing users to achieve ideal application results.

For the majority of engineers, the next content is closely related to the actual project, "how to install the pre-connected optical cable?" At the same time of product development, we specially designed the installation protection tube for this purpose, its function is to : First, ensure that the optical cable can withstand enough strength when placed in the pipeline or bridge, and the sealed structure ensures the dustproof and waterproof performance during the installation process, so its installation can be the same as in the past construction, and will not affect the optical fiber and optical cable. In case of any damage, the waterproof and protection grades reach IP50 and IP67 respectively.

Finally, the advantages of the pre-connection method are also reflected in the improvement and upgrade of the network. As mentioned above, the rapid changes in the application of the network will inevitably lead to changes and revisions of the network. However, due to the characteristics of the connection method used in the past, in many cases, customers It will be given up because the project is too complicated. In the end, the structure of the equipment room after expansion may be unreasonable, and the use and maintenance will become complicated and cumbersome. If the network terminal moves or the path changes, the customer only needs to select the appropriate time to pull out the pre-connected optical cable from the rack, and then re-clamp the optical cable splitter and fix it on the rack in the new position. The whole process is only It takes tens of minutes.

Combined with the above analysis, we summarize several characteristics of the application of pre-connected optical cables:

1) To protect the effectiveness and safety of the owner's investment, the pre-connected optical cable must be customized, which puts forward higher requirements for the integrator's ability to conduct preliminary and actual on-site investigations. The purpose is to fully protect the owner's right to control the project and the right to know the use of products. , to avoid the risk of material waste and project investment.

2) More economical The welding process requires machines, consumables, time and personnel, etc. In general, the pre-connection method does not increase additional costs.

3) Easy to operate, easy to install, save installation time, just plug and play as needed.

4) The loss test has been completed, the quality is stable, and the use is reliable. The pre-connected optical cable is 100% tested in the factory, and no other products are attached during the installation process, and the on-site test is simple.

5) The optical fiber link is fully protected. There is no splicing point and bare fiber exposed to the air, and there will be no worries about aging and joint breakage.

6) Easy and safe maintenance The mechanical properties of the pre-connected optical fiber splitter are excellent, and the maintenance or operation process will not affect the normal use of the optical fiber.

7)Can be re-installed and moved The splitter with pre-connected optical cables can be plugged and removed quickly and safely, and re-installed as needed. Entering the market from pre-connection, it has been applied in the design and construction of optical fiber networks in many telecom operators, finance, education, public security, customs, enterprises, science and technology parks, etc., and has also won high recognition from integrators and end customers. And wide acclaim, make us more confident, we hope more users can have such a fiber optic network with convenient construction, high security and excellent performance, because we always believe that network cabling is one of the most important parts of future applications , With a highly secure and reliable foundation, there will be more exciting and excellent network applications.