Optical fiber jumpers are equipped with connector plugs at both ends of the optical fiber cable. When selecting optical fiber jumpers, in addition to considering the connectors, it is also extremely important to identify the quality of the optical cable.

Fiber Jumper

method/step

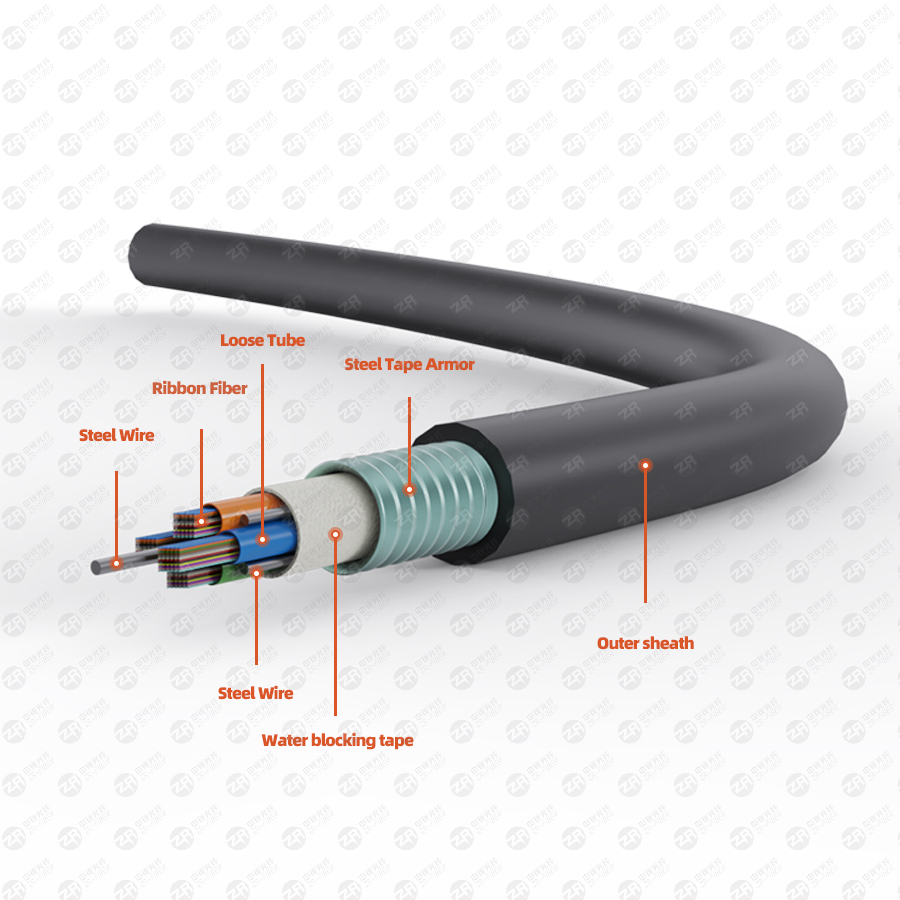

1. Outer sheath:

1. Indoor optical cables are generally made of polyvinyl chloride (PVC) or flame retardant polyethylene or polyurethane (LSZH). The appearance should be smooth, bright, flexible and easy to peel. Inferior fiber optic cables have poor finish and are easy to stick with tight sleeves and aramid fibers.

2. The outer sheath of the outdoor optical cable should be made of high-quality black polyethylene (HDPE, MDPE). The outer sheath of the inferior optical cable is generally produced with recycled materials. The surface of this optical cable is rough, because there are many impurities (lime powder) in the raw material. If you look closely, you can find that the outer sheath of the optical cable has many tiny pits. Whitening, it will crack and seep after laying for a period of time.

2. Optical fiber:

Regular optical cable manufacturers generally use the A-grade fiber cores of major manufacturers. Low-cost and low-quality optical cables usually use C-class, D-class optical fibers and smuggled optical fibers of unknown origin. These optical fibers are often damp and discolored due to complex sources and long delivery times, and multi-mode optical fibers are often mixed with single-mode optical fibers. However, the general small factory lacks the necessary testing equipment and cannot judge the quality of the optical fiber. Since such optical fibers cannot be distinguished by the naked eye, the common problems encountered in construction are: narrow bandwidth and short transmission distance; uneven thickness, which cannot be connected to the pigtail; the optical fiber lacks flexibility and breaks when the fiber is coiled.

3. Strengthen the steel wire:

The steel wire of the outdoor optical cable of the regular manufacturer is phosphating, and the surface is gray. This kind of steel wire does not increase the hydrogen loss after cabling, does not rust, and has high strength. Inferior optical cables are generally replaced by thin iron wires or aluminum wires. The identification method is very easy, that is, the appearance is white, and it can be bent at will when you hold it in your hand. The optical cable produced with such steel wire will generate additional hydrogen loss in the future, and at the same time, over time, the two ends of the hanging optical fiber box will rust and break.

Fourth, armored steel belt:

Formal production enterprises use double-sided brushed rust-proof and plastic-coated longitudinally-wrapped steel strips. Inferior optical cables are made of ordinary iron sheets, and usually only one side has been rust-proofed.

5. Optical fiber sleeve:

The loose tube of the optical fiber in the cable should be made of PBT material, which has high strength, no deformation, and anti-aging. Low-quality optical cables are usually made of PVC material.

Six, fiber paste:

The fiber paste in the outdoor optical cable can prevent the optical fiber from silver streak, hydrogen loss, and even breakage caused by moisture. Few fiber pastes are used in inferior fiber optic cables, and some air bubbles can be observed with the naked eye, or the use of inferior fiber pastes will seriously affect the service life of fiber optic cables.

7. Aramid:

Also known as Kevlar, it is a high-strength chemical fiber that is currently most used in the military industry. Military helmets and bulletproof vests are produced from this material. At present, the aramid fibers above the market are mainly produced by DuPont in the United States. Both indoor optical cables and power overhead optical cables (ADSS) use aramid yarns as reinforcements. Due to the high cost of aramid fiber (2,000 million yuan/ton), inferior indoor optical cables are generally made very thin in outer diameter, which can save costs by reducing a few strands of aramid. Such optical cables are easy to be pulled when passing through the tube. .

Eight, cable paste:

The fiber paste in the outdoor fiber optic cable is attached to the outside of the fiber optic sleeve to protect the fiber optic cable from moisture. Usually high-quality cable paste is evenly mixed, and there will be no separation after long-term use. In the inferior fiber optic cable, the cable paste will volatilize, or the filling will not affect the moisture barrier performance of the fiber optic cable.