Optical fiber, short for optical fiber, is a fiber made of glass or plastic that acts as a light-transmitting tool. Optical fiber network is very useful in life. Once a fault occurs, it will cause great trouble. How to troubleshoot common faults and troubleshooting methods of optical fiber network becomes more and more important.

Any professional who has done network troubleshooting knows that this is a complex process. Here are some of the most common fiber failures and the likely factors behind them, information that will help users make educated guesses about network failures.

In communication systems of various services, optical fibers have gradually replaced cables due to the low cost of optical cables, long transmission distances of optical signals, and low loss. Therefore, the failure of the optical cable line must be repaired against every second, especially in important application network systems. The following will gradually analyze the phenomenon that occurs in the optical fiber fault and determine the possible scope of the fault point.

Fiber Failure Causes

1. The main causes of optical cable failures

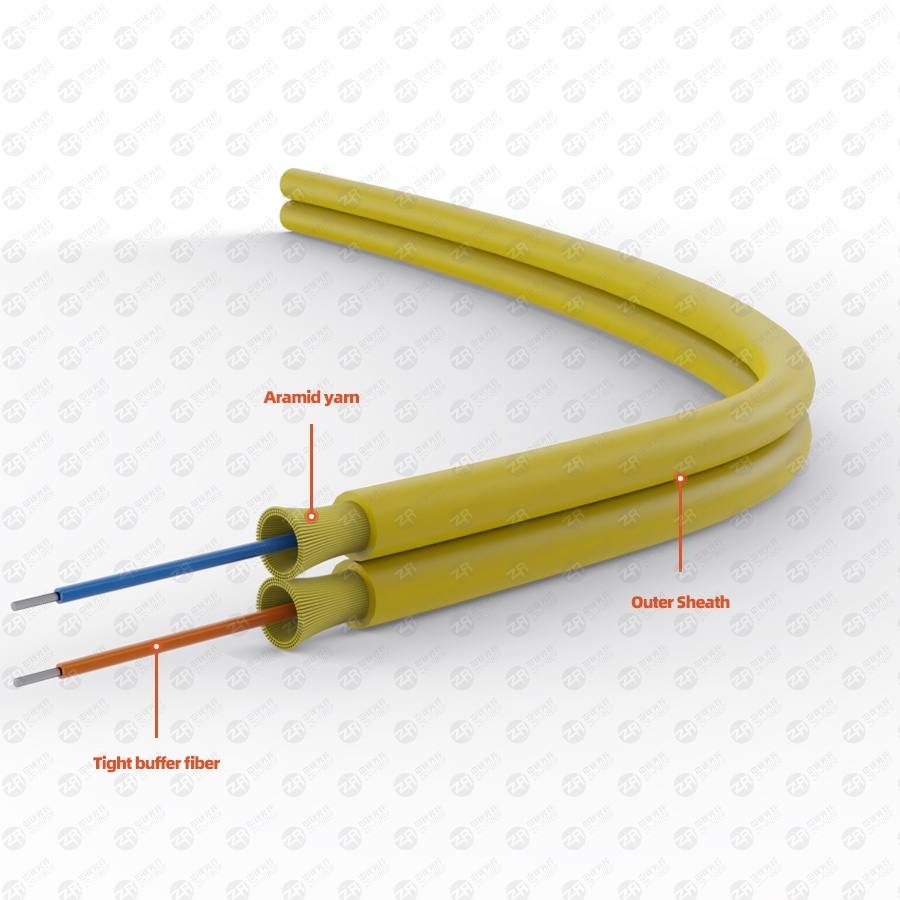

In order to ensure the long-distance and low-loss application characteristics of optical transmission signals, an optical cable line must meet certain physical environmental conditions. Any slight bending deformation of the optical cable or slight pollution will cause the attenuation of the optical signal and even interrupt the communication.

1. The optical cable routing line is long. Due to the physical characteristics of the optical cable itself and the inhomogeneity in the production process, the optical signal propagated in it is diffused and absorbed all the time. When the optical cable link is too long, the overall attenuation of the optical signal of the entire link will exceed the requirements of network planning, and the optical signal attenuation will be too large, which will reduce the communication effect.

2. The bending angle of the optical cable is too large The bending attenuation and pressure attenuation of the optical cable are essentially caused by the deformation of the optical cable, which cannot satisfy the total reflection during the optical transmission process. The optical fiber has a certain flexibility, but when the optical fiber is bent to a certain angle, it will cause the change of the propagation direction of the optical signal in the optical cable, resulting in bending attenuation. This requires special attention to reserve sufficient angles for the wiring during wiring construction.

3. The optical cable is compressed or broken. This is the most likely fault in the optical cable failure. The optical fiber is subjected to external forces or natural disasters, resulting in tiny irregular bends or even breaks. It is impossible to find the breakpoint, but the change of refractive index will occur at the breakpoint of the fiber, and even reflection loss will be formed, which will deteriorate the quality of the transmission signal of the fiber. At this time, use the OTDR optical cable tester to detect the reflection peak to find the bending attenuation or breaking point inside the optical fiber.

4. Fusion splicing failure during construction of optical fiber joints In the process of laying optical cables, optical fiber fusion splicers are often used to fuse two sections of optical fibers into one. Since the glass fiber in the core layer of the optical cable is spliced, it is necessary to use the fusion splicer correctly according to the type of optical cable during the welding process at the construction site. Due to the operation that does not meet the construction specifications and the change of the construction environment, the optical fiber is easily contaminated. Dirt, resulting in impurities mixed in the splicing process, resulting in a decrease in the communication quality of the entire link.

5. Different core diameters of optical fibers Optical fiber laying often uses a variety of active connection laying methods, such as flange connections, which are often used in the laying of computer networks in buildings. Generally, the loss of the active connection is low, but the end face of the fiber or the end face of the flange is not clean during the active connection, the diameter of the core fiber is different, and the splicing is not strict, which will greatly increase the loss of the joint. Core diameter mismatch faults can be found by testing with OTDR or double-ended power. It should be noted that, in addition to the diameter of the core fiber, single-mode fiber and multi-mode fiber have completely different light transmission modes, wavelengths, and attenuation methods, so they cannot be mixed.

6. Pollution of fiber optic connector The pollution of pigtail connector and damp fiber jumper are the main reasons for the failure of fiber optic cable. Especially in the indoor network, there are many short fibers and various network switching equipment, and the plugging and unplugging of optical fiber connectors, the replacement of flanges, and the transfer are very frequent. During operation, excessive dust, insertion loss, finger touch, etc., can easily make the optical fiber connector dirty, which will make the optical path unable to be adjusted or the optical attenuation is too large. Alcohol wipes should be used for cleaning.

7. Poor polishing at the connector Poor polishing of the connector is also one of the main faults of the optical fiber link. The ideal fiber cut plane does not exist in the real physical environment, and there are some undulations or slopes. When the light in the optical cable link encounters such a cut surface, the diffuse scattering of light and the reflection of light due to the irregularity of the joint surface will greatly increase the attenuation of light. On the curve of the OTDR tester, the attenuation area of the poorly polished cut surface is much larger than that of the normal end surface.

8. Point contact failure of optical cable joints Poor contact of joints mainly occurs in ODF frame optical cable distribution boxes and optical switches. The main reason is that the construction operation does not meet the standards, or the quality of the connecting equipment, or the failure of the connecting flange, etc., resulting in the insufficient sealing of the optical fiber connector, resulting in light reflection loss and leakage attenuation. Excessive use of fiber optic connectors will cause a significant drop in the transmission quality of the fiber optic cable. To sum up, the use of optical cables has many advantages, but its physical characteristics make optical fiber communication hidden troubles. External forces and natural disasters will cause the optical cable to be compressed or broken; impurities mixed in during fusion will cause changes in the quality of the optical path; core wire diameters are different; fiber cut surface pollution and poor polishing will cause changes in the direction of light transmission. The precision of optical fiber communication makes it difficult to detect optical fiber faults with the naked eye, which requires that in the process of optical fiber wiring, it is necessary to avoid unnecessary optical cable faults due to human reasons.

2. Find and judge the fault point of optical fiber

Obstacles occur in the maintenance of daily optical cables, and the following procedures are usually used to find and judge.

1. Check whether the indicator light of the photoelectric converter is normal (take the TOEC photoelectric converter as an example). If the optical port (FDX) indicator of the photoelectric converter is not on, if the optical port (FDX) indicator of the transceiver is not on, please confirm Whether the fiber link is cross-linked, one end of the fiber jumper is connected in parallel; the other end is connected in a cross-connection. If the optical port (FDX) indicator of the A transceiver is on and the optical port (FDX) indicator of the B transceiver is not on, the fault is on the A transceiver side; the cause of the fault may be: the A transceiver (TX) optical transmission port has been Bad, because the optical port (RX) of the B transceiver cannot receive the optical signal; another possibility is: there is a problem with this optical fiber link of the optical transmission port of the A transceiver (TX) (the optical cable or optical jumper may be broken ).

2. Determine whether the fiber optic cable and fiber pigtail line are faulty

(1) On-off detection of optical cable and optical fiber jumper: use a red light pen to send red light to one end of the optical fiber connector or coupler, and check whether there is red light at the other end. If there is red light, the optical cable or optical fiber jumper is not broken. . The flange or pigtail cut surface is damaged due to external physical factors, or it is intermittently turned on and off due to the vibration of the equipment. This kind of failure adopts the method of replacing the flange or pigtail.

(2) Use an optical power meter to measure both ends of the fiber optic cable pigtail to see if there is a reading to determine whether the optical cable or fiber jumper is broken. At the same time, be sure to clean the pigtail connection points, flanges, and equipment ports with alcohol.

3. Use OTDR (Optical Time Domain Reflectometer) to test

(1) During the test, if there is no curve on the display screen, the fault point of the optical fiber is in the blind area of the instrument, including the tail of the optical cable, the connecting joint between the optical cable and the pigtail, and the flange. You can add a pigtail to reduce the blind area. The breakpoint of the fiber.

(2) The far-end position of the reflection curve on the screen does not match the actual length of the optical cable, and there are obvious "steps" in the curve. If this is the joint, it means that the joint is unqualified or the bending radius of the optical fiber in the joint box is too small. Or squeezed; if this is not the joint, it means that the optical cable is squeezed or bent sharply.

(3) The curve shows a strong Fresnel reflection peak at the far end, indicating that the fiber end face is perpendicular to the fiber, indicating that this is an end point instead of a breakpoint, and the fault point may be on the terminal connector (flange or ODF frame).

(4) There is no reflection peak at the far end of the curve, indicating that the end face is a broken fiber surface, and the most likely fault is the fusion point between the optical cable and the pigtail. The curve shows that there is no reflection peak at the far end, but there is a protruding curve, indicating that there is a crack in the optical fiber, resulting in loss. Check the fusion point between the optical cable and the pigtail.

(5) The curve shows the high loss area and the high loss point. The slope of the curve is obviously larger, indicating that the fiber quality of this section is not good and the attenuation is larger. If the high attenuation point is the same as the joint part, it means that the joint has a large loss and can be re-spliced. It may also be that the optical cable is deformed by force, resulting in the loss of the optical fiber due to external force. After using the optical time domain reflectometer to determine the location of the fault point, arrive at the site of the fault range:

①If the optical cable is broken by external force, repair it by welding immediately.

②If the single line is interrupted and it is in the splice box, carefully check the fiber tray in the splice box, pick out the splicing points one by one to check whether the fiber core has single fiber shrinkage or breakage, and re-splicing if the fault point is found. The loose fiber in the fiber accommodating disk will cause the fiber to bounce on the edge of the fiber accommodating disk or be squeezed by the screws on the disk. In severe cases, the fiber will also be crushed and broken.

③ If there is neither a fusion point nor a breakpoint of external force at the fault point, the optical cable route of this section should be observed with the naked eye. There is trauma caused by external force on the surface of the optical cable. By checking the severity of the damage point, it is necessary to judge whether it needs to be re-welded or needs to be picked up.

3. Conclusion

From the advent of optical fiber communication to the present, optical fiber transmission technology has had a huge impact on the development of the entire social economy. Only by mastering the detection methods of fault points of optical cable lines can you accurately judge and determine the location of the obstacle points, and be proficient in the operation procedures of line repair and the use of equipment, so as to improve the repair time. Only flexible testing and comprehensive analysis can solve problems faster and better in optical fiber troubleshooting.