In fiber optic network infrastructure, since patch cords are fragile, ZR Cable provides the correct operating procedures for optimal performance and reliability.

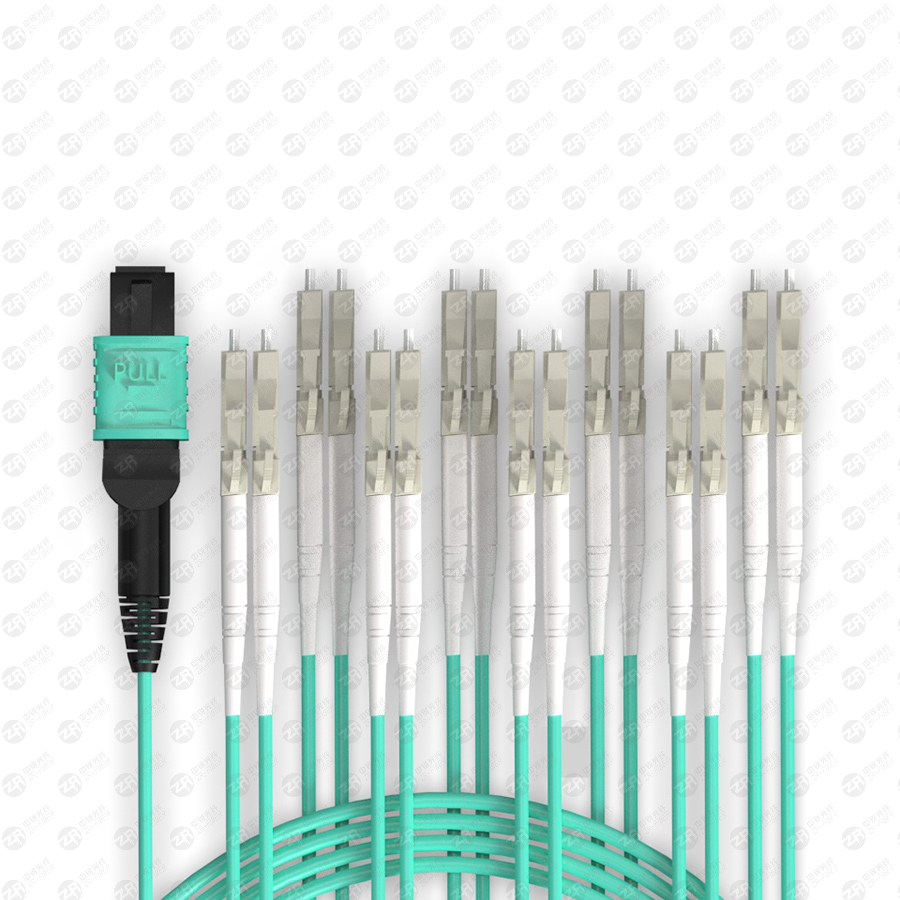

Fiber Jumper

1. Both ends of the fiber jumper must be optical modules with the same wavelength. The simple way to distinguish them is that the colors of the optical modules should be the same.

2. Under normal circumstances, short-wave optical modules use multi-mode optical fibers (usually orange), and long-wave optical modules use single-mode optical fibers (usually yellow) to ensure the accuracy of data transmission.

3. Do not bend and loop the optical fiber excessively during use, which will increase the attenuation of light during transmission. The minimum bending radius of the optical fiber is less than 30mm.

4. After the optical fiber jumper is used, it is necessary to protect the optical fiber connector with a protective sleeve. Dust and oil pollution will damage the coupling of the optical fiber.

5. If the optical fiber connector is dirty, you can use a cotton swab dipped in anhydrous alcohol to clean it, otherwise it will affect the communication quality.

6. Before use, the ceramic ferrule and the end face of the ferrule must be wiped clean with alcohol and absorbent cotton.

7. Protect the ferrule and the end face of the ferrule to prevent bumps and pollution, and put on a dust cap in time after disassembly.

8. Do not look directly at the end face of the fiber when the laser signal is transmitted.

9. In the event of man-made or other force majeure damage, the damaged fiber jumper should be replaced in time.

10.Or further use a precision optical fiber insertion loss and return loss instrument to test its various indicators. If the indicators are within the qualified range, the jumper indication is normal, otherwise it is unqualified.