The so-called optical fiber end face treatment, also known as end face preparation, is a key process in optical fiber technology, mainly including stripping, cleaning and cutting. as follows:

1. Stripping of optical fiber coating

Removing the fiber coating is the first step in fiber end face treatment. Stripping can be done with both wire strippers and a blade. When stripping with a wire stripper, pinch the optical fiber with the thumb and index finger of the left hand, and the exposed length is about 5cm. The remaining fiber is naturally bent between the ring finger and the little finger to increase the strength and prevent slipping. The wire stripper should be perpendicular to the optical fiber. , incline upwards at a certain angle, then lightly clamp the fiber with the jaws, then force the right hand to push it out along the axis of the fiber, the whole process should be natural and smooth, and strive for a success; Soak the 3~5cm long optical fiber end in concentrated sulfuric acid for 1~2 minutes, and wipe it clean with alcohol cotton [2].

Pinch the fiber tightly with the left hand, hold the fiber flat to prevent slipping, and use the blade with the right hand to follow the direction of the fiber to the end, at a certain angle to the fiber, and strip the polymer material of the surface coating layer in sequence. The solvent method has the disadvantage of serious corrosion of the optical fiber by immersing it for a long time, and it is easier and cleaner than directly scraping with a wire stripper or a blade, and it is not easy to damage the side part of the optical fiber cladding.

2. Cleaning of the cladding surface

Observe whether the cladding of the stripped part of the optical fiber is completely removed. If there is any residue, it must be removed. If there is a very small amount of coating that is not easy to be stripped, use a cotton ball to dip an appropriate amount of alcohol, dipping it and wiping it off. Tear the absorbent cotton into small fan-shaped pieces with a flat surface, dip a little alcohol (it is advisable to squeeze two fingers together without overflowing), fold it into a V shape, clamp the stripped optical fiber, and wipe it along the axial direction of the optical fiber. Cotton should be replaced in time after 2 to 3 times of use, and different parts and layers of cotton should be used each time, which can not only improve the utilization rate of cotton, but also prevent secondary pollution to the surface of the fiber cladding.

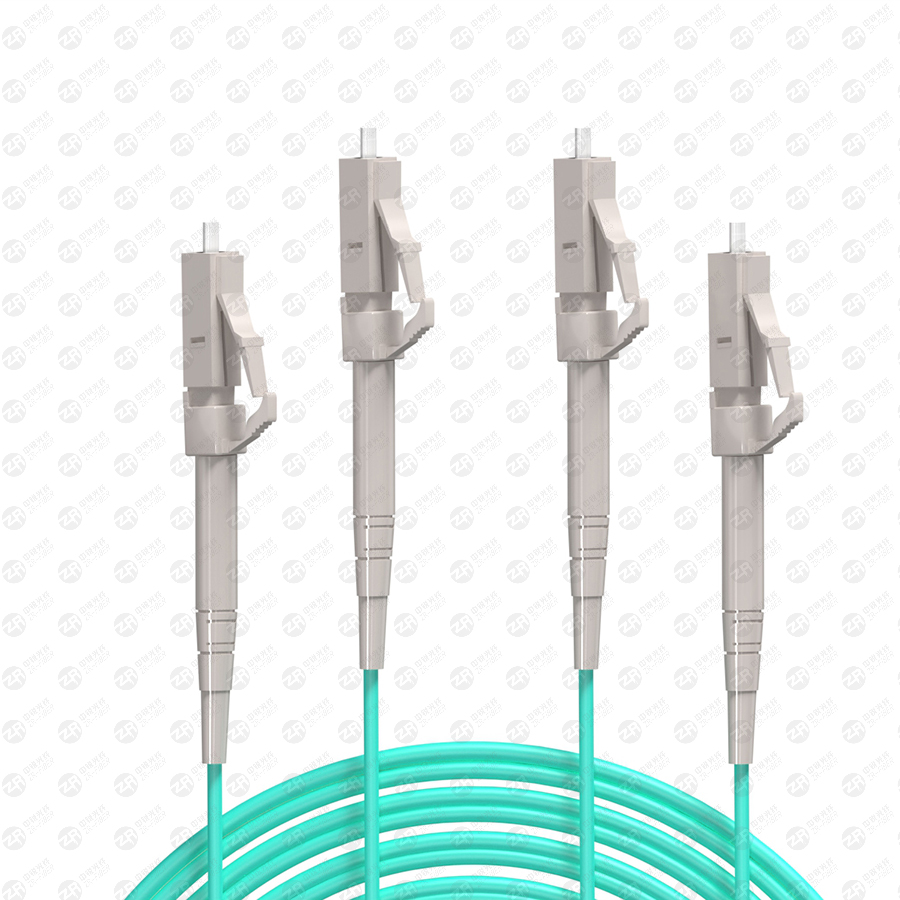

3. Fiber end face cutting

Cutting is the most critical step in the preparation of optical fiber endfaces. Precision and high-quality cutters are the foundation, and strict and scientific operating specifications are the guarantee. Commonly used cleavers include pen cleavers and desktop fiber cleavers. When using a pen-type cleaver to cleave the fiber, place the fiber on your finger, and hold the knife about 5mm away from the end to cleave the fiber in the direction perpendicular to the fiber axis, and then gently remove the cut end; use a desktop fiber When operating the cleaver, first clean the cleaver blade, the V-groove for placing the optical fiber and the positioning platen, and adjust the position of the cleaver to make it stable. When cutting, the action should be smooth and natural, not heavy or urgent, to avoid the occurrence of bad end faces such as broken fibers, bevels, burrs and cracks.

The cleaning and cutting time of the surface should be closely connected, and the interval should not be too long. In particular, the prepared end face should not be placed in the dirty air. When moving, handle it with care to prevent it from rubbing against other objects.