In the process of integrated wiring, the most indispensable part is the fiber optic cable. However, many friends are often puzzled, what is the difference between optical fiber and optical cable, and how to distinguish the quality of optical cable? Let's go and find out together.

What is the difference between optical fiber and optical cable

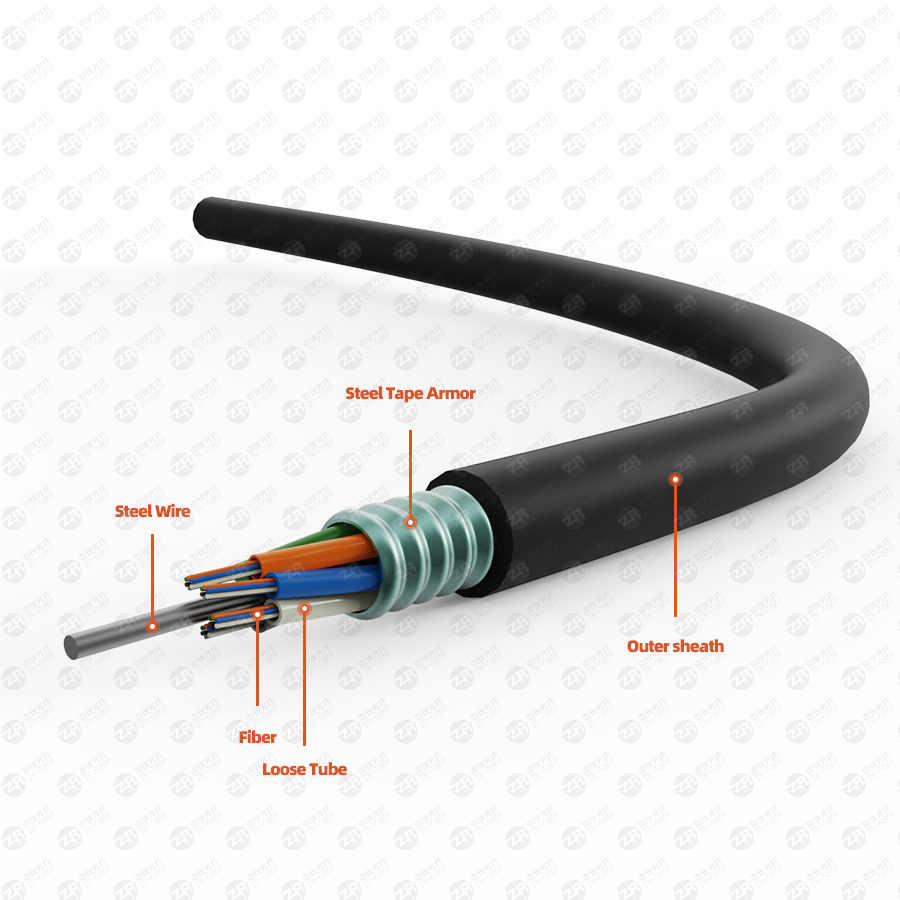

1. Optical fiber is a thin and soft medium that transmits light beams. Most optical fibers must be coated with several layers of protective structures before use, and the coated cable is called a fiber optic cable. Therefore, the optical fiber is the core part of the optical cable, and the optical fiber constitutes the optical cable through the protection of some components and the auxiliary protective layer.

The protective structure of the outer layer of the optical fiber can prevent the damage of the optical fiber from the surrounding environment. Optical cables include optical fibers, buffer layers and cladding. Fiber optic and coaxial cables are similar, just without the mesh shield. At the center is the glass core where light travels.

Optical fibers are usually bundled and protected by a jacket. The fiber core is usually a double-layer concentric cylinder made of quartz glass with a small cross-sectional area, which is brittle and easy to break, so an external protective layer is required. So that's the difference between them.

2. Optical fiber cable: It is mainly composed of optical fiber (glass filament as thin as hair), plastic protective sleeve and plastic outer skin. There is no metal such as gold, silver, copper and aluminum in the optical cable, and generally has no recycling value. Optical cable is a kind of communication line in which a certain number of optical fibers form a cable core according to a certain method, which is covered with a sheath, and some are also covered with an outer sheath to realize optical signal transmission. That is, the optical cable is formed by the optical fiber (optical transmission carrier) through a certain process.

Advantages of optical cables Optical fiber cables are a new generation of transmission media. Compared with copper media, optical fibers have greatly improved in terms of security, reliability and network performance. The bandwidth of optical fiber transmission greatly exceeds that of copper cable, and the maximum distance supported is more than two kilometers. Optical fiber cable has the advantages of good electromagnetic interference resistance, strong confidentiality, fast speed and large transmission capacity.

There are two different types of optical fibers that are more common at present, namely single-mode optical fiber and multi-mode optical fiber. Multimode fiber is generally used for network connections in the same office building or in relatively close areas. Single-mode fiber, on the other hand, delivers higher quality data and longer distances, and is often used to connect networks between office buildings or more geographically dispersed networks. If the optical fiber cable is used as the network transmission medium, it is necessary to add equipment such as optical transceivers.

fiber optic cable

How to distinguish the quality of optical cable

1. Ointment.

The ointment mainly includes fiber paste and cable paste. Under normal circumstances, the fiber paste should fill the entire loose tube, and the cable paste should fill every gap of the optical cable core under pressure. At present, the fiber paste is half full or less, and some cable pastes are only applied on the outside of the cable core, and some are not filled in the middle of the two ends of the optical cable.

In this way, the optical fiber will not be well protected, affecting the transmission performance such as optical fiber attenuation, and the poor waterproof performance cannot meet the national standard. Once the optical cable sees water accidentally, the entire link will be scrapped. Under normal circumstances, even if there is accidental water seepage, it is only necessary to repair the seepage section, and there is no need to start over.

(The national standard requires water blocking performance: three meters of optical cable, one meter of water column pressure, no water seepage for 24 hours.) If poor ointment is used, the above problems will also occur, and it may be due to the poor thixotropy of the ointment. , it will cause micro-bending loss of the optical fiber, and the transmission characteristics of the entire link will be unqualified; if the ointment is acidic, it will react with the metal material in the optical cable to react with H to precipitate hydrogen molecules, and the attenuation of the optical fiber will increase rapidly when it encounters H, resulting in the entire Link interrupt transmission.

2. Sheath.

The optical cable jacket should not only adapt to many different and complex climatic environments, but also ensure long-term (at least 25 years) stability. The optical cable jacket should not only have a certain strength, low thermal deformation, wear, water permeability, thermal shrinkage and friction coefficient, but also have the characteristics of strong environmental stress resistance and good material processing performance.

Although less or poorly used sheath materials can pass the factory inspection, cracking and water seepage will occur after a period of use due to quality defects. If recycled plastics are used to replace high-quality polyethylene sheath materials, it will be even more serious.

The optical cable made of high-quality sheath material has a flat, bright, uniform thickness and no air bubbles after the cable is formed. Otherwise, the surface of the optical cable will be rough, and there are many impurities in the raw material. If you look closely, you can find that the outer sheath of the optical cable has many extremely small Wow, and because of its thin thickness, the entire outer diameter of the fiber optic cable will be much smaller than that of a high-quality fiber optic cable.

Indoor optical cables are generally made of high-quality flame-retardant polyvinyl chloride. The appearance should be smooth and bright, with good flexibility and easy peeling; otherwise, the outer skin will have poor finish, and it will be easy to stick to the tight-sleeve fiber and aramid fiber.

3. Steel strip, aluminum strip.

The steel tape and aluminum tape in the optical cable are mainly used to protect the optical fiber from mechanical side pressure and moisture resistance. Chrome-plated steel tape is generally used in better optical cables. Inferior optical cables use ordinary iron sheets or black sheets (uncoated steel strips) with only one side that has been rust-proofed to replace chrome-plated steel strips. Over time, rust will occur in the optical cable, and the hydrogen loss of the optical fiber will also increase. It is easy to separate from the sheath to form a comprehensive bonding protective layer, and the moisture blocking performance is also very poor; some use tin-plated steel strips instead of chrome-plated steel strips, and the surface of tin-plated steel strips, air bubbles, etc. are unavoidable.

Therefore, corrosion is prone to occur in humid atmosphere and surface condensation or water immersion conditions, especially in acidic conditions. The tin-plated layer has poor heat resistance, and the melting point is only 232 degrees Celsius. Due to the high temperature when extruding the sheath, there is uncertainty in the peel strength, which affects the moisture resistance of the optical cable.

The melting point of chromium is 1900 degrees Celsius, and its chemical properties are very stable. It will not rust when placed in the air or immersed in water at room temperature. For aluminum tapes, unqualified thermal-lamination-coated aluminum tapes are generally used instead of cast-casting-coated aluminum tapes, which will also affect the performance of the optical cable.

4. Steel wire.

The steel wire in the cable is mainly used to protect the optical fiber from mechanical tension.

Good optical cables generally use high-modulus phosphating steel wire with a short-term tensile force of 1500N or 3000N. The inferior optical cable will be replaced by iron wire or ordinary steel wire with a small diameter, which is easy to corrode;

On the other hand, since the tensile strength is far less than 1500N, the fiber may be damaged during construction. High-modulus phosphating steel wire is generally blue-gray, has good toughness, and is not easy to bend; while the alternative iron wire can be bent at will when it is held in the hand for a long time, and the two ends of the hanging fiber box will rust and break.

5. Loosen the casing.

The loose tube of the optical fiber in the optical cable is generally made of polymer PBT material (polybutylene terephthalate). Such a loose tube has high strength, no deformation, and anti-aging. The loose tube of the inferior optical cable is sometimes replaced by other materials. The outer diameter is very thin, and it will be flattened when pinched by hand. It is no different from the drinking straw and cannot protect the optical fiber.

6. Water blocking belt.

The water-blocking tape or water-blocking yarn for optical cable has strong water absorption properties through the evenly distributed superabsorbent resin inside the product. Under the combined action of penetration pressure, affinity and rubber elasticity, the superabsorbent resin can quickly Inhale water several times its own weight.

Moreover, once the water blocking powder meets water, it will swell the gel immediately, and no matter how much pressure is applied to it, the water will not be squeezed out. Therefore, if the cable core is covered with a water-blocking tape containing a water-absorbent resin, in case the outer wall of the optical cable is damaged, the super-absorbent resin in the wound portion will expand to exert a sealing effect, thereby preventing the entry of water to a minimum.

Inferior optical cables usually use non-woven fabrics or paper tapes. Once the outer sheath of the optical cable is damaged, the consequences will be very serious.

7. Aramid.

Also known as Kevlar, it is a high-strength chemical fiber, which is currently most used in the military industry, and bulletproof vests are produced from this material.

It is a DuPont patented product and is the main cost component of indoor optical cables. It is mainly used to protect the tight-buffered fibers in indoor optical cables from mechanical tension. However, due to the high cost of aramid fiber, inferior indoor optical cables generally make the outer diameter very thin, which can save costs by reducing a few strands of aramid fiber, or use a polyester yarn similar in appearance to aramid fiber instead (already common) , while polyester yarn can hardly bear any tension. In this way, the optical fiber is easily pulled or broken during laying.

8. Optical fiber.

Optical fiber is the core raw material in optical cables, and good optical cables generally use high-quality fiber cores from major manufacturers. Inferior optical cables usually use low-grade optical fibers and smuggled optical fibers of unknown origin. These optical fibers are difficult to guarantee due to their complex sources. Sometimes multi-mode optical fibers are often mixed with single-mode optical fibers. Generally, small factories lack the necessary testing equipment and cannot detect optical fibers. The quality of the judgment is made, which makes it difficult to guarantee the quality.

In addition, some buy short sections of optical fibers at low prices and then make them into optical cables. Since such optical fibers cannot be distinguished by the naked eye, the problems often encountered in construction are: low transmission rate, short distance, large optical fiber attenuation, inability to connect with pigtails, lack of flexibility, easy to break when coiled, and even one fiber is damaged. Multimode, the other end is singlemode.

9. Coloring ink.

In order to facilitate the identification of optical fibers during construction, the national standard requires that the optical fibers and loose tubes should be colored with bright colors. The high-quality optical cables are colored with high-quality ink according to the standard, and the colors are very bright and not easy to fall off. The inferior optical cables will be colored with inferior ink or No coloring at all. Inferior inks are not bright in color and are sometimes easy to dissolve in the fiber paste, resulting in indistinguishable colors. No coloring brings great inconvenience to construction.

10. Product packaging.

Optical cables are generally packaged in wooden or iron-wood reels, and the outside of the reels will be sealed with wooden sealing plates to ensure that the stress and bending radius of the bulky optical cables during transportation are within the standard requirements.

In order to save costs, low-quality optical cables generally use very poor packaging reels, which are almost disintegrated when they are transported to the destination. Some simply do not use reels, wrap the optical cables and ship them, or use reels to seal without wooden strips.

To sum up, the real difference between the advantages and disadvantages of optical fiber cables comes from the comprehensive difference between the advantages and disadvantages of their structural design, materials and production processes. Because optical cables are still not widely popularized, and although inferior products have many hidden dangers, many users and even integrators still use them regardless of the occasion.

It is for this reason that inferior optical cables will have a greater negative impact on the industry, because as far as the optical cable itself is concerned, its value is not great, but the cost of its laying process (direct burial, overhead, pipe penetration, etc.) is very staggering. It is time-consuming and labor-intensive, and it is the basic medium in the entire communication link, so once a problem occurs, no matter how expensive and high-end the hardware devices at your two ends are, the entire system will be completely paralyzed without exception, and the repair cycle will be very long. , the loss will be ten million times the difference between the good and the bad.

In general, after so many years of adjustment in China's optical fiber and cable market, the price-performance ratio of domestic high-quality optical cables has become the highest in the world. Blindly participating in competition at low prices must sacrifice product quality and damage customer benefits. The final result It will be an unhappy breakup between buyers and sellers, and I hope all practitioners and users will be cautious.

The above is all about the difference between optical fiber and optical cable and how to distinguish the quality of optical cable. Because of the common use of optical cable, the market of optical cable has gradually expanded. The expansion of the market will inevitably bring some bad phenomena. In order to make huge profits, some inferior optical cables are produced as high-quality sales, so the quality of optical cables must be carefully identified.