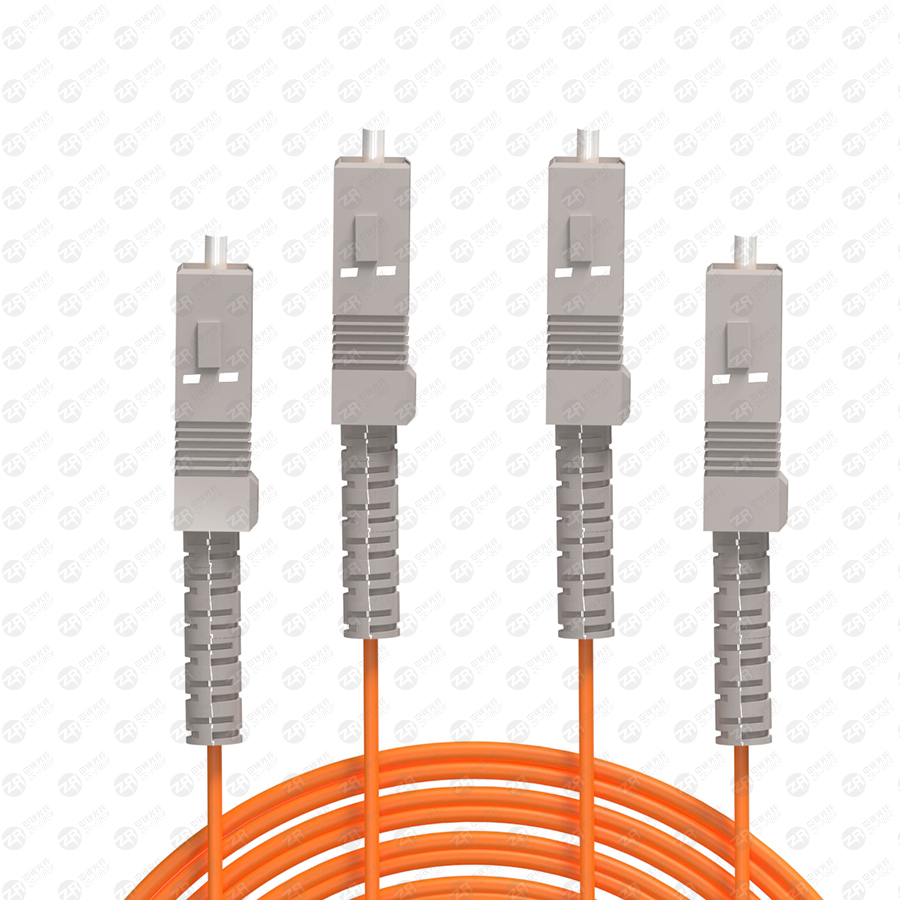

Fiber patch cords are used to make patch cords from equipment to fiber optic cabling links. There is a thicker protective layer, which is generally used for the connection between the optical transceiver and the terminal box.

Pigtail, also known as pigtail, has only one end with a connector, and the other end is a broken end of a fiber optic cable core. It is connected to other fiber optic cable cores by welding. It often appears in fiber optic terminal boxes. (couplers, jumpers, etc. are also used between them).

Optical fiber connector is a device for detachable (active) connection between optical fiber and optical fiber. It precisely connects the two end faces of optical fiber, so that the light energy output by the transmitting fiber can be coupled to the receiving fiber to the maximum extent. And minimize the impact on the system due to its involvement in the optical link, which is the basic requirement of fiber optic connectors. To a certain extent, fiber optic connectors also affect the reliability and performance of optical transmission systems.

How to check whether the fiber jumper is qualified

Use an insertion and return loss tester to first measure whether the jumper is clear with a light-passing pen, and make sure that the optical fiber is not broken. The general carrier-level test indicators: the insertion loss is less than 0.3dB, and the return loss is greater than 45dB.

The performance testing of optical fiber jumpers is divided into:

1. Optical performance test Including return loss/insertion loss test, the test instrument can use FibKey 7602 return loss/insertion loss integrated tester.

2. End face geometry test Parameters tested include curvature radius, vertex offset, fiber height, etc. The test instrument is an interferometer, and many people use NorlandAC/NC3000 or CC6000 for testing. Especially the CC6000 interferometer is used by more and more factories because of its superior cost performance.

3. Optical fiber end face scratch detection Use video optical fiber magnifier to observe, for example, many factories use FibView FV-400PA for inspection. The instrument gives the clearest images and is extremely easy to operate. Some customers also use the FibKey-5600 variable magnification magnifier for testing. The instrument integrates 400x, 200x, and 80x magnifiers, which can clearly and conveniently observe the fiber end face and the ferrule end face. Of course, you can also use the relevant software to automatically check.

4. Optical fiber tensile test It is necessary to test the tensile force that the optical fiber connector can withstand.

5.Ambient temperature experiment It is necessary to test the performance indicators of optical fiber connectors under different ambient temperatures.

https://www.ductcable.com/cordSearch?patchTopType=3&subType=1