In fiber optic cable assemblies, the polishing process is probably the most critical step in ensuring high-quality assemblies that meet specifications. Therefore, it is important to choose the correct fiber polishing machine and polishing fixture for your needs. Depending on the cable manufacturer's offering, it's likely that you have multiple polishing units that produce different fiber connector styles.

The quality of the polishing unit (also known as the polishing plate or fixture) is critical to your company. Given the high cost of producing equipment and components, your company will need to maintain these tools in the long run to produce high volumes with minimal quality issues.

Proper maintenance of polishing units is critical

The polishing fixture of the optical fiber polishing machine is manufactured with high-precision processing equipment. Fixtures made of steel and aluminum can bend and warp over time, which can negatively affect the polishing process and product quality. On the other hand, polishing units made of hardened stainless steel avoid this wear. However, hardened stainless steel contains more iron in the alloy, so it does increase the risk of rusting. This is a key reason why proper maintenance is so important.

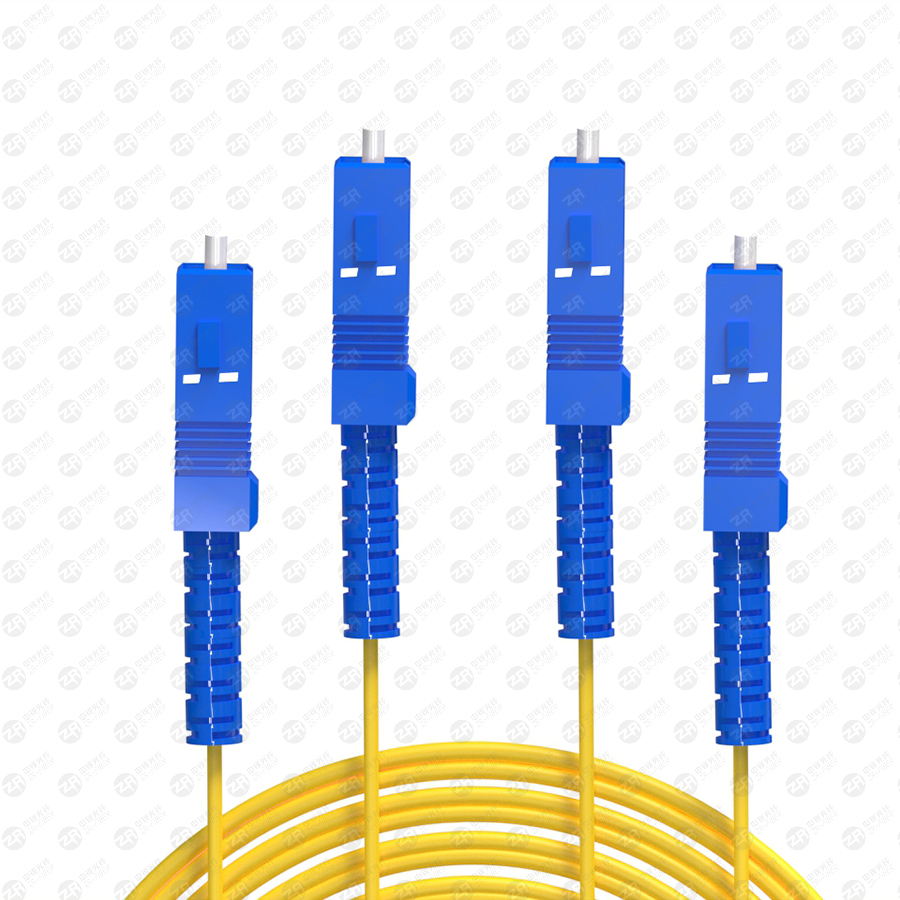

sc fiber optic connector

Additionally, the most common connectors (SC fiber optic connectors, LC fiber optic connectors, and E2000 fiber optic connectors) are locked to polishing fixtures by plastic latches or clamps, and they will wear out over time if not cleaned properly. Poor cleaning techniques can also prevent proper locking. This can seriously affect the functionality of the polisher, which in turn affects the quality of the product.

Polishing units are expensive – this is the fundamental reason why proper maintenance is so important. With routine maintenance, you can use the polishing fixture for extended periods of time without changing the quality level of the cable assembly.

Follow these 8 steps to clean and maintain your polishing unit

Whether your company is just beginning to manufacture fiber optic cable assemblies or you have many years of experience, we recommend that you strictly follow these guidelines for proper cleaning and maintenance of polishing fixtures.

It's better to clean for 5 minutes a day, not 30 minutes a week. In fact, we recommend that you integrate cleaning routines into your daily polishing process. During polishing, cleaning fixtures should be a regular task and a priority.

Use distilled water as it does not contain abrasive minerals. Do not use tap water - ordinary drinking water varies around the world. Your company's tap water may contain iron minerals that tend to stick to polishing devices. Also, don't use alcohol. In fiber optic centers, we recommend the use of an air-cleaning cleaning wand. This handheld cleaning wand features an integrated pressurized fluid and filter system for debris-free cleaning.

Ferrule holes (for MT-style fixtures, ferrule grooves, surrounding surfaces, and top clamps) can be cleaned with a toothbrush and particle-free distilled or deionized water. Likewise, don't use alcohol. For fixtures with 1.25mm diameter ferrule holes, we recommend a 1. 25mm nylon brush (purple handle brush). For a 2.5mm diameter ferrule hole, use a 2.5mm nylon brush (blue handle brush). For type MT fixtures, either will work fine. Clean the jig while it is still wet during polishing. This makes it easy to remove polishing debris.

To clean areas that the brush cannot reach, use an ultrasonic bath. When using an ultrasonic bath, the deionized water must be changed daily. Otherwise, debris may contaminate the polishing jig. (Again, here's a link to the Air Cleaner cleaning wand datasheet.) If your device has a cam lock interface, pay special attention to the spring seam. They are very narrow and tend to accumulate debris, which causes the metal to bend less and interfere with spring function. After cleaning the polishing jig, it is important to dry it thoroughly to avoid rust. This is especially true for polishing jigs made of hardened stainless steel.

Your polishing results may change over time, and the reasons may be directly related to the natural wear and tear of the critical interface of the polisher and fixture. The EZ-Check Precision Wear Gage Kit provides precise measurements of polished mandrels, fixture mounting holes and ferrule holes. We recommend incorporating this wear gauge kit into your process control system. Call the Fiber Center to determine if the tool is suitable for polishers and fixtures. Click to read the data sheet for Domaine Engineering's EZ-Check Precision Wear Gauge Kit.

Extra Tips

Monitoring the face geometry of the polishing ferrule is an excellent way to monitor the quality of the polishing fixture. Any major imperfections in the fixture will be reflected in the end face geometry parameters.

For example, a change in Vertex Offset may indicate that the fixture holes may be worn or contaminated. A change in radius could indicate a bad latch or a worn clamping mechanism. When this happens - if the polishing process hasn't changed - it may be a good time to replace the plastic latch or polishing jig.

in conclusion

As mentioned earlier, the polishing process is probably the most critical step in ensuring high-quality fiber optic cable assemblies. We hope these maintenance and cleaning guidelines will help you make better use of these critical tools to avoid quality issues and avoid the rapid deterioration of this expensive equipment.