I believe every fiber manufacturing company should build their own test cords. Of course, these test leads must provide accurate, repeatable insertion loss (IL) test results.

This article provides guidance to confidently construct and use EF-compliant "modally transparent" test leads (also known as reference and launch leads).

How to Build Your Own Modal Transparent Multimode Test Leads In a nutshell, why is "EF compliance" important? Today, most multimode test systems are designed and manufactured to ensure EF-compliant light output. The IEC initiated the EF-Compliance standard to facilitate standard multimode test initiation conditions for consistent, repeatable insertion loss test results.

EF-compliant launch conditions reduce the occurrence of "overfilled" and "underfilled" launch conditions, both of which can lead to inaccurate IL test results:

Excessive launch conditions – In excess launch conditions, the optical power leaving the test leads is spread out in a large "spot size" - possibly larger than the size of the fiber core. When connecting to a device under test (DUT), even if the receiving connection is of good quality, a significant amount of optical power at the OD at that point will not couple into the core of the receiving fiber. The results add to the (incorrectly poor) insertion loss test results.

Underfilled launch condition – Conversely, in underfilled launch condition, optical power exits the test leads in a small "spot size" concentrated in the center of the core. When connected to a DUT, most light is easily coupled into the core of the receiving fiber, even if the two cores are severely misaligned. The result is a false good insertion loss test result.

Keep in mind that the emission conditions of the customer's transmission equipment are unknown and will vary depending on the type of light source (laser or LED) and the manufacturer of the light source. The purpose of EF compliance is not to standardize the start-up conditions for end-user transmission equipment, but to standardize the test equipment of cable assembly manufacturers so that test results from all fiber manufacturing companies can be "split in two".

Chances are, you won't maintain EF-Compliance throughout your test setup. The reasons are as follows:

Many fiber optic manufacturing companies go wrong by not understanding that using an EF compliant light source alone is not enough to ensure that the light emitted from the test leads is still EF compliant. An EF-compliant light source ensures that light exiting the source has controlled and mode-specific conditions. It is the manufacturer's responsibility to ensure that your test leads are constructed of high-quality connectors and fibers to maintain the required modal conditions.

Connecting poor quality test leads (or switches or any other components in the test system) to a light source can drastically change the modal conditions of the light source, even if the light source itself does meet EF. Now, the light emitted from the test leads is no longer controlled and may not be EF compliant.

How do you maintain EF-Compliance?

The best way to ensure that EF-Compliance is maintained throughout the test is to ensure that all fibers (switches, test leads, etc.) within the optical path of the test system are as "modally transparent" as possible. That is, the fibers and connections throughout the optical path should be designed to have a minimal effect on changing the modal conditions of the optical input.

Typically, fiber optic cable assembly manufacturers build their own multimode test leads using low-cost/low-quality fibers and connectors, regardless of how these factors affect output modal conditions. Ideally, you can use a commercially available EF meter to directly measure the EF-Compliance at the test lead output. However, the reality is that very few fiber optic manufacturing companies have invested in this equipment. This is relatively expensive, and manufacturers tend to view multimode assemblies as "low-level" fiber optic cable assemblies and should not focus on the testing details required for "high-level" single-mode assemblies. However, even without a dedicated EF meter, it is not difficult to build test leads that can maintain EF-Compliance with a high degree of confidence.

To build a "modally transparent" multimode test cord to help maintain the modal conditions of an EF-compliant test light source, you should:

Use the highest quality fiber available, polished to industry standards – High quality metrology grade multimode fiber is available from most major fiber manufacturing companies. Ask your fiber supplier; they should be familiar with this fiber.

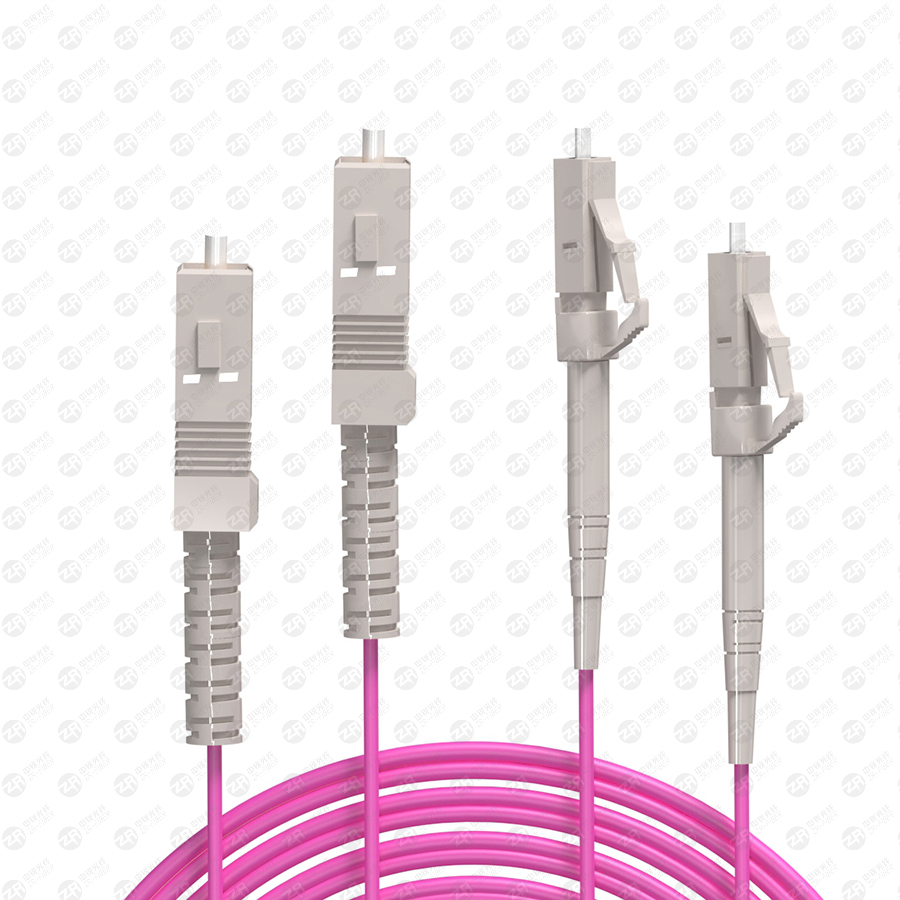

Terminate these fibers with high-quality connectors – I recommend using good-quality single-mode fiber connectors on all multimode test leads. These will have adequate ferrule hole concentricity and hole ID tolerances. Use connectors with high concentricity/low diameter ferrule holes. This is important, not only at the end of the test leads used for testing, but also at the ends of the test leads that will be connected to the light source. If those two fiber cores are not properly aligned, the modal conditions will change.

The ferrules are polished to meet standard single-mode end face geometry and visual inspection standards – this helps ensure optimal core-to-core contact in all connector mating.

bottom line

You can build and confidently use your own "modally transparent" multimode test leads to adequately maintain the modal conditions of incoming light from EF-compliant light sources. This will give you more accurate, repeatable IL test results!