Sometimes, there are situations where you need to cross over fibers. The reasons may vary, but in the end, it will be necessary to cross transmit (TX) and receive (RX) to establish a proper connection.

One of those situations is where you have to make connections, and instead of going straight through the fiber, fiber optic manufacturers run them through. In other words, when you try to plug in, you have to get TX from one end, but the other end should also be TX, which definitely doesn't work.

Having said that, you need to pick up the TX and plug it into the RX on the other side of the port - this is actually what's called a crossover. You need to ensure the type of connector you are dealing with. If the fibers are reversed, all you need to do is pull out the fibers, criss-cross them and put them back in, and the connection is made.

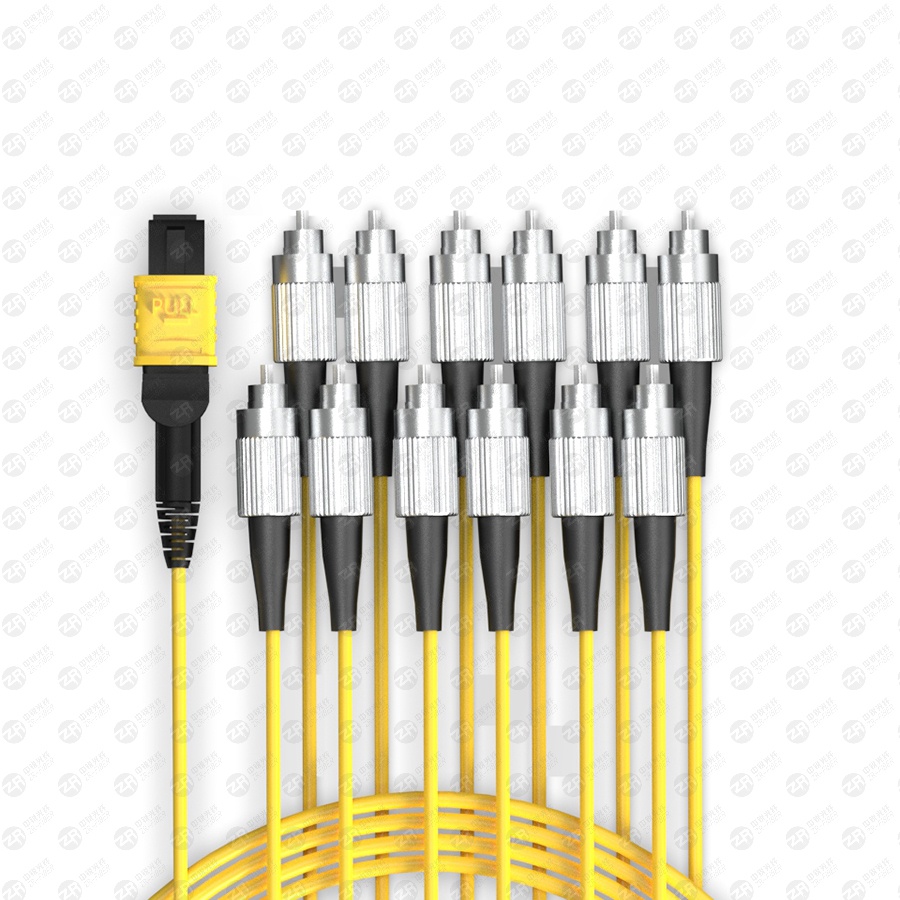

fiber optic cross-connect

One thing that has to be made clear is that you should be able to correct both ends correctly whenever you do a crossover. This is a great way to prevent confusion and misfortune in the future.

For example, you may have done a cross-connect in a panel with hundreds of panels. So this is not only an inconvenience for you, but also for the rest of the team who are responsible for managing these connections.

lc connector

Another case you might have is an LC connector on both sides. To cross these fibers, all you need to do is remove the fiber optic connectors from the retaining brackets and cross them manually. To do this, first determine how the connector is assembled. For example, if they split at the bottom, the fiber should stick out from the bottom, so you'll need to figure out a way to pull the fiber out and repeat the process for the other fiber.

Then make sure to handle with care not to bend any of the fibers too much to avoid breaking, then reinstall the carrier onto the fiber and watch the connector mechanism carefully to make sure it seals properly. Occasionally, a clicking sound is heard when the bracket is locked. Also, make sure both connectors are the same height so that a proper connection can be made when plugged in.

Another situation you may encounter is that in one of the cases there may be a different type of mounting bracket on one end. In this case, you will need to pull the fiber out of the holder. Just be very careful about orienting so that you can maintain the orientation after tearing the bracket apart for a proper crossover. Once you have the correct bracket, insert the fiber into it and make sure to link properly.

Note that each bracket has its own specific mechanism, so study it carefully for a good change. If you feel the fibers are working too hard, or the mechanism is not loosening naturally, you may be doing the wrong thing and risk breaking the fibers.

Long story short, the reason fibers need to be crossed is simple: when connecting fibers from one device to another, the fiber wires must be twisted so that the TX reaches the RX on both ends. So if you encounter the above situation, you don't need to worry. Fibers can and must be crossed. Just make sure to make the necessary adjustments in subtle but effective ways to properly establish the connection you want.