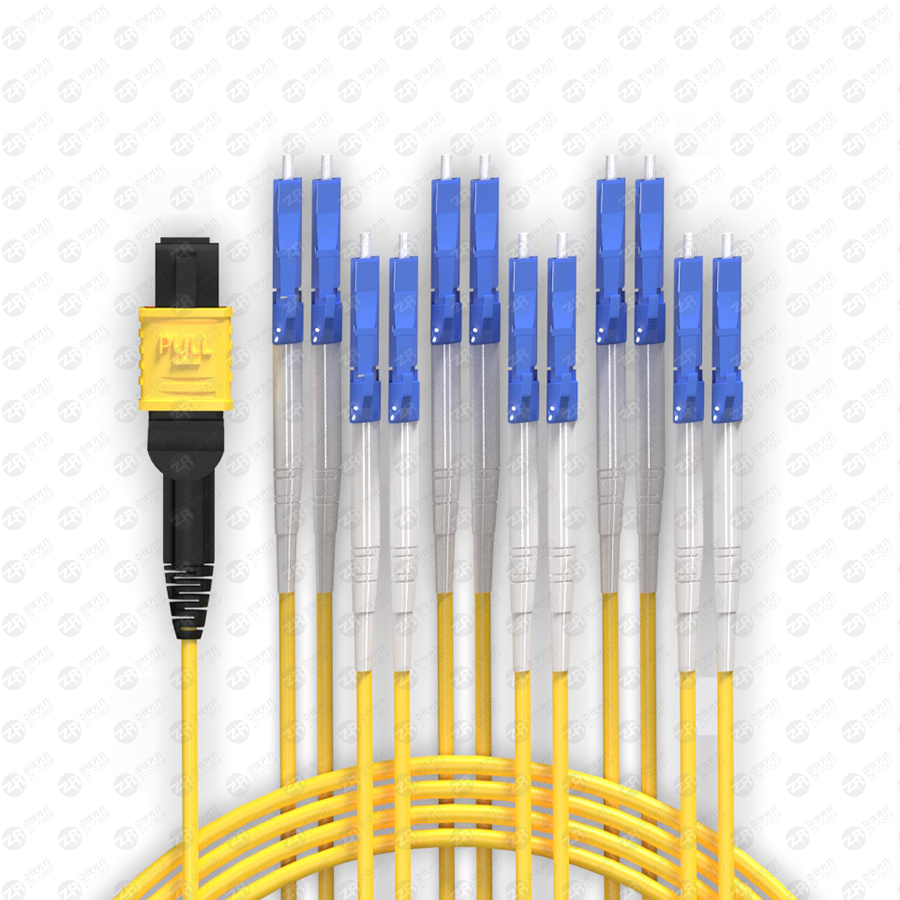

The research and development of MPO fiber optic connectors and the application in practical engineering play an important role and significance. It greatly improves the popularity of optical networks and reduces costs. It is a very important application in optical fiber communication networks, transmission systems and CATV networks. For example, the birth of MPO fiber jumper.

MPO fiber jumper transmission

At the same time, the application of MPO fiber jumper high-density wiring in practical engineering has an important role and significance. The use of MPO fiber jumper is a very particular knowledge and skill, and it is also a very important link. The following are the possible problems of MPO fiber jumpers and the corresponding solutions:

1. Guide pin hole damage

The main reason is that the insertion direction of the male head is inclined during the connection, and the front end of the guide pin of the male head is scratched and scratched. Such damage can directly lead to an increase in part or all of the channel loss value.

Solution: Try to avoid opening the dust cap before connecting the MPO fiber jumper. Try not to remove the dust cap from the adapter interface that has been connected to the adapter panel but has not been docked. Except for normal mating, do not allow the ground end of the connector to come into contact or scratch with anything else.

2. The end face is dirty

It is mainly caused by prematurely removing the dust cap before docking or exposing it to a non-clean environment for a long time. Such contamination will directly affect the docking performance of the product, making the docking effect unstable, and even causing damage to the opposite connector during docking.

Solution: If there is foreseeable dirt on the end surface, try to use special cleaning tools or clean paper soaked with absolute ethanol to clean the end surface. Do not use paper towels, cotton wool, ordinary cotton swabs and other items to clean the end surface.

3. Mechanical damage of parts

It is mainly caused by the excessive application of external force during the construction process. Such damage may not affect the performance in the initial stage, but it will basically fail completely in the short term.

Solution: When docking the connector, confirm that the connector positioning key direction is backward and the adapter or socket panel is inserted axially. Do not repeatedly insert and pull out without being able to view the end face. When inserting the MPO connector into the adapter, pay attention to the part of the connector boot, and when pulling it out, hold the part of the connector shell.

4. Cable mechanical damage

If it is mainly caused by dragging or unintentional cutting during construction, such damage may not affect the performance in the initial stage, but it will basically fail completely in the short term.

Solution: When bending the cable, keep the bending radius equal to or greater than 20 times the outer diameter of the cable. When bundling cables, keep the tightness appropriate, and the cable sheath must not be severely deformed. When perforating and threading the cable, use the method of pushing and pulling. Do not pull or push the cable vigorously to prevent the cable from being broken or broken due to scratches.

In order to meet the more comprehensive application of MPO fiber optic patch cords, ZR Fiber manufacturers have developed and produced a rich and complete range of fiber optic patch cords and their peripheral products. You can buy them all in one stop and save more time. If you have optical fiber needs, please contact us by email.

https://www.ductcable.com/product?productId=76e847f37ebc4b76b47696c8d7e718fc