Pay attention to the infeed depth when stripping the optical cable.

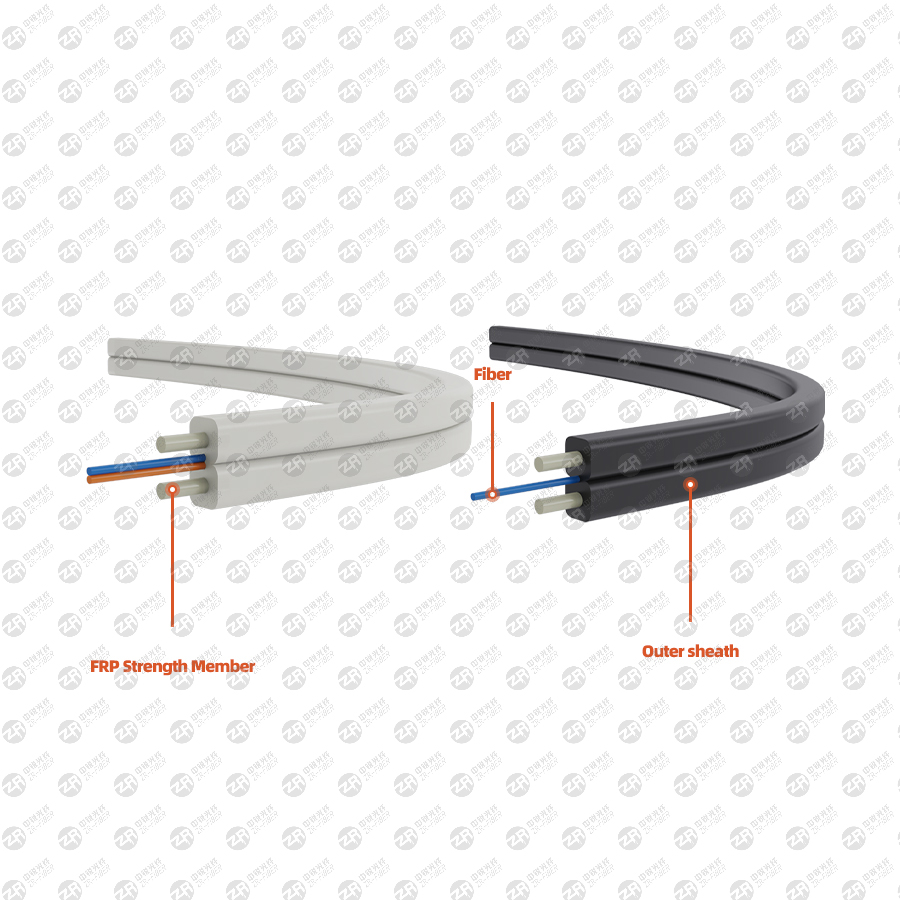

The optical cable splice box manufacturer tells you that the key to stripping the outer sheath of the optical cable is to master the depth of the sheath cutting knife, otherwise fiber breakage will easily occur. In actual operation, the sheath cutting knife should be rotated while observing the incision. If a white polyester tape can be seen, the knife should be stopped and the cutting knife should be removed. This step is a skilled process, and it takes many practice to master the depth of feed.

The fixing of the optical cable and the stripping of the fiber core bundle.

After the optical cable is stripped, fix the optical cable in the optical cable splice box, open and strip the fiber core bundle, and do all the preparations before the optical fiber fusion splicing.

Attention should be paid to the following when connecting optical fibers:

a) The core bundle tube cannot be twisted. Before fixing the optical cable, you must pay attention to the position of the core bundle tube. When the reinforcing member passes through the fixing screw, the underside of the reinforcing member must be the filling bundle tube, not the core bundle tube. The core bundle tube must be in the position where the reinforcing member enters the optical fiber. The same side of the receiving tray cannot be twisted on the reinforcement.

b) The length of the reinforcement should be appropriate. After the position of the core bundle tube is determined, the optical cable can be fixed. The fixation of the optical cable must ensure that the position of the optical fiber in the splice box will not be loosened, so as to avoid the problem of increased optical fiber loss or fiber breakage due to the movement of the optical cable position.

c) The stripping length of the core bundle tube should be appropriate. After the optical cable is fixed, the fiber core bundle can be opened and stripped. If the stripping length is too long, it will reach the groove of the fiber heat shrinkable tube, and the remaining fiber will be damaged when the fiber is coiled. .

Optical fiber splice box application scenarios

3. Fiber fusion.

The splicing of the optical fiber is directly related to the quality and life of the project, and the key lies in the preparation of the optical fiber end face. The fiber end face is smooth, without burrs or defects, the fusion splicer can accept the confirmation well, and can make joints that meet the engineering requirements. Meet engineering requirements.

4. Protection of residual fiber

After the optical fiber is spliced, it is necessary to protect the optical fiber with a heat-shrinkable tube and to reserve the remaining fiber.

Attention should be paid to:

a) During the fiber coiling process, the bending radius of the coiled fiber should not be too small, generally not less than 4mm. If the bending radius is too small, it is easy to cause excessive refraction loss and increased dispersion. Over time, fiber breakage may also occur.

b) When coiling the fiber, pay attention to the twisting direction of the fiber, which is generally an inverted "8" shape. Be careful not to twist the fiber. After the coil is completed, put all the fiber under the baffle of the receiving tray to avoid damage to the fiber during packaging.

5. The splice box produced by the optical cable splice box manufacturer is sealed

In practical engineering, the sealing of optical cable splice box is very important. Because the surface of the optical fiber is prone to micro-cracks after the splice box enters the water, the optical fiber will break after a long time, and most of the splice boxes are buried underground, so the sealing of the splice boxes must be done well.

The optical cable splice box manufacturer tells you that the sealing of the splice box is mainly the sealing of the two parts between the optical cable and the splice box and the upper and lower covers of the splice box. When sealing the optical cable and the splice box, first grind the optical cable sheath at the sealing place, and use gauze to grind the outer sheath vertically to the axial direction of the optical cable, so that the optical cable and the sealing tape can be combined more tightly and sealed better. . The sealing between the upper and lower cover plates of the joint box is mainly to pay attention to that the sealing tape should be evenly prevented from being in the sealing groove of the joint box, and the screws should be tightened without leaving a gap.

https://www.ductcable.com/product?productId=fbc88920466847918896b7fe86f91771