Nowadays, the wiring of large-scale monitoring systems generally adopts optical fiber transmission, because optical fiber not only has long transmission distance, small signal attenuation, but also has strong anti-interference ability. Due to these advantages, more and more engineers use special fiber optic patch cords for monitoring systems in monitoring system engineering. What are the precautions for monitoring the fiber optic cabling of the system?

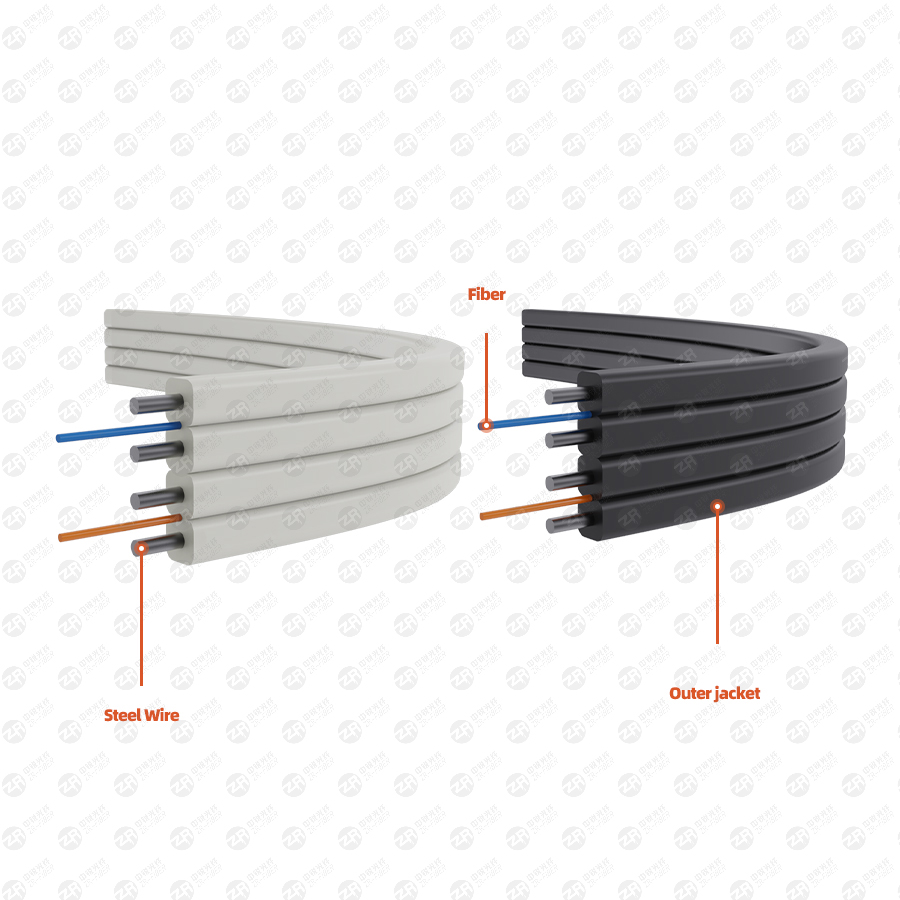

Carrier-grade single-mode dual-core fiber optic cable

First of all, you need to understand the characteristics of optical fibers, in addition to those mentioned above, including thin wire diameter, light weight, large transmission bandwidth, security, confidentiality, moisture resistance, high temperature resistance, corrosion resistance, etc.

Therefore, due to the thin wire diameter and light weight, when we route the optical fiber, the optical fiber must be routed so as not to bend the optical fiber and prevent the optical fiber of the optical fiber from breaking.

At the same time, the selected fiber optic patch cords for monitoring systems should also be equipped with corresponding supporting products, such as fiber optic junction boxes, junction boxes, fiber optic transceivers, pigtails, couplers, etc. These should select suitable fiber optic equipment according to different types of engineering requirements.

Make sure to use optical transceivers and when to use them. These days, it's usually a webcam. The fiber optic transceiver used to convert optical signals into digital signals is the signal of the RJ45 interface. Still other monitors are analog monitors, analog monitors that use optical transceivers, and optical transceivers that convert optical signals to BNC interfaces.

Carrier-grade single-mode dual-core optical fiber cable application scenarios

Optical fibers are multimode and singlemode, and we usually use singlemode fibers in monitoring engineering. When purchasing equipment, you should choose equipment that supports single-mode fiber.

The fusion splicing methods of optical fibers are divided into hot splicing and cold splicing. The monitored item is usually a hot melt because the cold end is unstable.

The last point is to keep the optical fiber 1-2 meters underground when wiring the dedicated optical fiber jumper for the monitoring system, and make a sign for future debugging and maintenance.