Description:

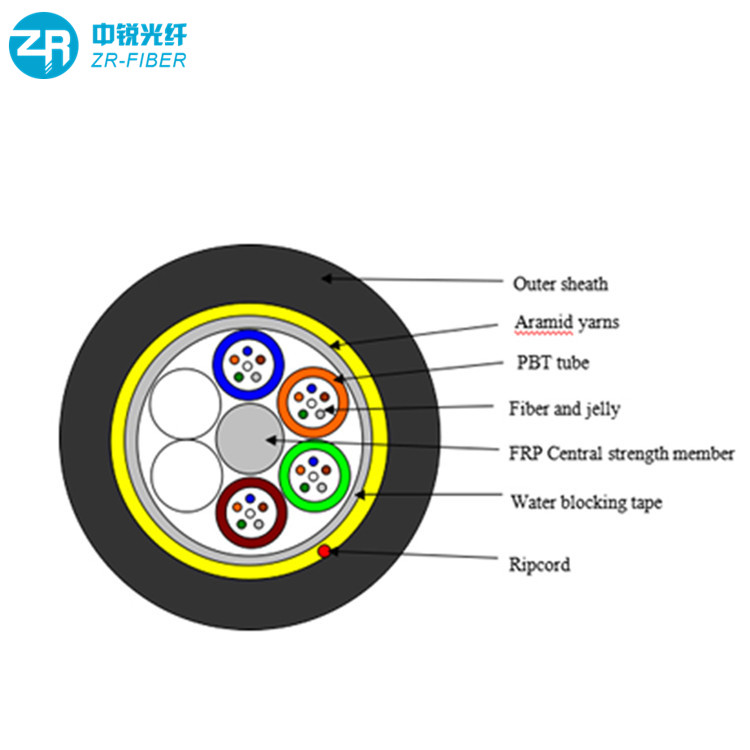

The fibers, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. The cable core is filled with filling gel to protect it from water ingress. The kevlar yarn surrounded the cable core as the reinforce strength member, then the cable is completed with a PE sheath.

Characteristics:

Good mechanical and temperature performance High strength looes tube that is hydrolysis resistant Special tube filling compound ensure a critical protection of fiber Crush resistance and flexibility Loose tube filling compound 100% cable core filling.

Applications:

ADSS optical fiber cable plays a significant role in the communication industry. Its usage is gradually increasing with more people choosing it in expense of other fiber cable. Some of its outstanding features have enhanced its demand throughout the market. This article analyses the key applications of the ADSS optical fiber cable. The research showed that, ADSS optical fiber cable’s demand is high particularly in areas of transmitting high-voltage power.

Reliable Lifetime Performance

1.Exclusive fiber coating (single mode) for permanent embedded color

2.Custom engineered for operation under full load

3.Optional track-resistant jacket prevents dry-band arcing damage for line voltages 275 kV ( 20kV space potential)

4.Guaranteed standards-based performance

Easy Cable Entry & Preparation

1.Ripcord speeds cable entry & outer jacket removal

2.Swellable binders speed cable preparation

Technical Parameter:

| Span (meter) | Weight(kg/km) | Diameter(mm) | Initial Tension (N) Unload Load | |

| 600 | 162 | 13.60 | 17500 | 17852 |

| 700 | 173 | 13.90 | 21600 | 22200 |

| 800 | 178 | 14.20 | 24200 | 24320 |

| 900 | 184 | 14.50 | 36200 | 36800 |

| 1000 | 189 | 14.80 | 42700 | 42950 |

| 1100 | 195 | 15.10 | 47300 | 47600 |

| 1200 | 201 | 15.40 | 52600 | 52960 |

| 1300 | 207 | 15.70 | 57200 | 57600 |

| 1400 | 212 | 16.00 | 62500 | 62800 |

| 1500 | 217 | 16.30 | 66300 | 66650 |

| 1600 | 223 | 16.60 | 68900 | 69263 |

| Fiber Type | G.652 | G.655 | 50/125μm | 52.5/125μm | |

| Attenuation (+20X) | 850 nm | <3.0 dB/km | <3.3 dB/km | ||

| 1300 nm | <1.0 dB/km | <1.0 dB/km | |||

| 1310 nm | <0.36 dB/km | <0.40 dB/km | |||

| 1550 nm | <0.22 dB/km | <0.23 dB/km | |||

| Bandwidth | 850 nm | >500 MHz-km | >200 Mhz-Km | ||

| 1300 nm | >500 MHz-km | >500 Mhz-Km | |||

| Numerical Aperture | 0.200±0.015NA | 0.275±0.015NA | |||

| Cable Cut-off Wavelength cc | <1260 nm | <1480 nm | |||

Ref. Outer | Ref. Weight | Rec. Daily Max. (kN) | Max Allowable | Break Strength (kN) | Strength Member CSA (mm2) | Modulus of (kN/mm2) | Heat Expansion Coefficient (x10- 6/K) | Suitable Span | ||||

PE Jacket | AT Jacket | A | B | C | D | |||||||

12.5 | 125 | 136 | 1.5 | 4 | 10 | 4.6 | 7.6 | 1.8 | 160 | 100 | 140 | 100 |

13.0 | 132 | 142 | 2.25 | 6 | 15 | 7.6 | 8.3 | 1.5 | 230 | 150 | 200 | 150 |

13.3 | 137 | 148 | 3.0 | 8 | 20 | 10.35 | 9.45 | 1.3 | 300 | 200 | 290 | 200 |

13.6 | 145 | 156 | 3.6 | 10 | 24 | 13.8 | 10.8 | 1.2 | 370 | 250 | 350 | 250 |

13.8 | 147 | 159 | 4.5 | 12 | 30 | 14.3 | 11.8 | 1.0 | 420 | 280 | 400 | 280< Now contact price discount price!窗口背景

Contact usLeave a messageCopyright © 2005-2022 Hunan Zhongruiguang Communication Equipment Co.,Ltd. All rights reserved Information submitted... Later, please

|